Newsletter about nutrient stewardship - European Sustainable Phosphorus Platform (ESPP)

Please subscribe www.phosphorusplatform.eu/Subscribe

Link to www.phosphorusplatform.eu/eNews096

Download as PDF

Events

10-12 June 2025, Bergen, Norway: nutrients in aquaculture and fisheries workshop

Nutrient sustainability in livestock

Workshop outlines key messages for UNEP white paper

Calls

ESPP call for consultant: feasibility of recycled P ‘quotas’ in fertilisers

Help ESPP continue sharing free information on phosphorus sustainability

Sign the joint stakeholder call for nutrients in the EU Circular Economy Act

Public consultations open

Open: EU consultations on simplification of sustainability reporting

Open: EU consultation on next EU budget framework

New ESPP member

LIFE Phos4EU – demonstration of vivianite recovery

Policy

EU Battery Recycling Regulation to require phosphorus to be accounted

EU phosphate supply: can Europe find enough P without Russian imports ?

EU Clean Industrial Deal (CID): decarbonisation, circularity

EU Green Deal progress assessment

Circular Economy Act

EURIC (recycling industry) priorities

Italians call for ambitious Circular Economy Act

Netherlands associations proposals for Circular Economy and End-of-Waste

Nutrient recycling

CleanTeQ Water delivering first PHOSPHIX® ion-exchange P-recovery plant

Stercore manure pyrolysis project validated

EasyMining confirms funding for first Ash2Phos plant

Research

Food phosphate additives widespread in US foods

Stay informed

ESPP members

Events

10-12 June 2025, Bergen, Norway: nutrients in aquaculture and fisheries workshop

ESPP workshop, with partners in Norway and UNEP uPcycle, on nutrient management in aquaculture: fish feed, seafood processing and fish sludge valorisation, Norway & online, 10-12 June 2025, covering nutrient flows, environmental best practice, phosphorus recycling, regulatory challenges. The workshop will contribute to the United Nations (UNEP) project uPcycle, leading to a UNEP white paper on phosphorus sustainability in aquaculture. Site visits to in-sea fish farm with sludge recovery, research installations, fish sludge processing.

One or two slots are still available for presentations of fish and aquaculture industry nutrient sustainability actions, fish feed industry, fish sludge nutrient recycling. Programme, registration https://phosphorusplatform.eu/AquacultureFisheries

Nutrient sustainability in livestock

Workshop outlines key messages for UNEP white paper

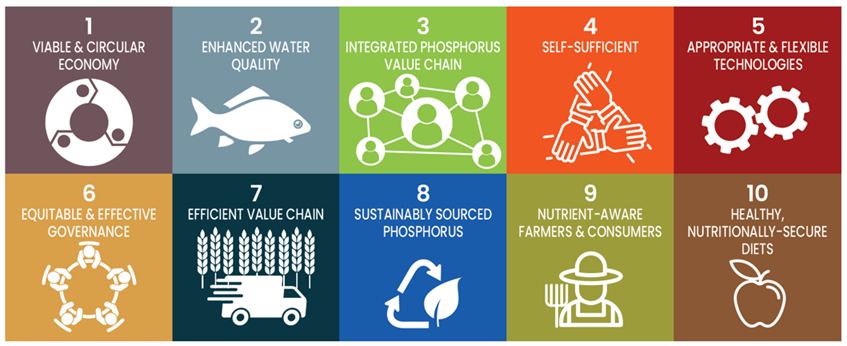

ESPP - UNEP uPcycle project workshop outlines draft principles (one page) for sustainable nutrient management in livestock - open for comment. Full workshop summary including presentations by the European Commission, UNEP, FAO, industry and research. Over one hundred participants took part at this workshop, organised in Saint Malo, Brittany, and online, with TIMAC AGRO (the leading activity of the Groupe Roullier), Cooperl (the Brittany pig farmers’ cooperative), ESPP, BETA Tech Center (Vic University, Spain) and CEH UK, in Saint Malo, Brittany, France, 5-7 March 2025, as part of the United Nations UNEP GEF uPcycle project. The workshop summary includes proposed Key Messages for the UNEP white paper on nutrients in livestock (one page).

ESPP SCOPE Newsletter n° 155 (18 pages), April 2025 “Phosphorus sustainability in livestock” www.phosphorusplatform.eu/Scope155

Comments are welcome on these proposed Key Messages.

Calls

ESPP call for consultant: feasibility of recycled P ‘quotas’ in fertilisers

ESPP is looking for an industry consultant or economics and market expert to outline and assess the feasibility and possible mechanisms for ‘quotas’ for recycled phosphorus in fertilisers (minimum recycled nutrient content requirements). The aim is to produce of a 5-page brief, outlining potential approaches to defining and implementing recycled P quotas and identifying associated opportunities, challenges and possible unintended consequences. This should consider different fertiliser product categories (including both mineral and organic fertilisers, both commercial and ‘on-farm’), national or EU-level targets, company overall or per-product … The work will include: collating relevant literature (including published analysis of ‘quotas’ in other sectors), first draft paper, refinement of this draft via 2-3 online or stakeholder meetings, finalisation of briefing paper with references. The paper aims to contribute to EU policy developments on nutrient circularity (see ESPP’s stakeholder proposals for market pull policies to support nutrient recycling and for nutrients in the EU Circular Economy Act). Objective is to finalise the paper by end September 2025

Work will be funded and published by ESPP. Expressions of interest to ESPP by 9th May to

Help ESPP continue sharing free information on phosphorus sustainability

We have launched a crowdfunding campaign to sustain free access to our information and resources, in particular this eNews and SCOPE Newsletter. Your support is essential to keep knowledge on phosphorus sustainability open to all.

ESPP is committed to sharing open, up-to-date and (as far as feasible) objectively validated information on phosphorus sustainability, recycling, and innovation — essential for environmental protection, food security, and the circular economy. Through our website, eNews, SCOPE Newsletter, and social media, ESPP provides free, open-access information on the latest technologies, scientific research, and policies related to phosphorus. We connect stakeholders across industries, encourage innovation, and share best practices to advance sustainable phosphorus management.

ESPP operates without public subsidies, relying solely on membership fees. This funding model, while preserving our independence, limits our capacity to expand activities and to continue providing high-quality information, by making the full content of the eNews, SCOPE Newsletter and our website freely accessible. Your support can help us to continue the free distribution of up-to-date information on phosphorus sustainability, promote recycling innovation and facilitate cross-sector dialogue and collaboration. If you believe in open access and a more sustainable future, please consider making a donation. Every contribution helps keep knowledge flowing!

Donate here: https://gofund.me/e25dfa8c

Sign the joint stakeholder call for nutrients in the EU Circular Economy Act

To sign this joint call, contact ESPP, specifying your organisation name, signatory contact, logo.

The EU Circular Economy Act is currently under preparation. This will be the first EU legal Act (Parliament and Council) for circularity and recycling, replacing the Commission’s Circular Economy Action Plans 1 and 2, and is has been announced as part of the new Commission’s Clean Industrial Deal (see below).

Now is the time to input to this proposed Act, which is expected to include changes to Waste legislation, Public Purchasing, producer responsibility, and aims to boosting consumer demand for recycled materials.

ESPP has prepared detailed technical input, addressing nutrient circularity in a wide range of regulations and policies www.phosphorusplatform.eu/regulatory

All organisations are invited to co-sign the 1-page “joint call for nutrients in the EU Circular Economy Act” www.phosphorusplatform.eu/regulatory

Public consultations open

Open: EU consultations on simplification of sustainability reporting

Public consultations on modifications to EU Sustainability Reporting Standards, as part of the Commission’s ‘Omnibus’ simplification package. See ESPP eNews n°95.

European Commission ‘Omnibus Package’ announcement 26th February 2025 “Commission simplifies rules on sustainability and EU Investments” https://ec.europa.eu/commission/presscorner/detail/en/ip_25_614?link_id=a2a47574-5401-4cc8-95c7-0c429f73aeed

EFRAG public consultation (under mandate from the European Commission) on simplification of the European Sustainability Reporting Standards (ESRS) open to 6th May 2025 https://survey.alchemer.eu/s3/90824354/ESRS-Set-1-revision-Questionnaire-for-public-feedback

Open: EU consultation on next EU budget framework

EU public consultation on post-2027 Multiannual Financial Framework (MFF), to inform the architecture of the EU budget for the next 5-10 years. See ESPP eNews n°95.

“EU’s next long-term budget (MFF) – performance of the EU budget”, public consultation, open to 6th May 2025 https://ec.europa.eu/info/law/better-regulation/have-your-say/initiatives/14526-EUs-next-long-term-budget-MFF-performance-of-the-EU-budget_en

New ESPP member

LIFE Phos4EU – demonstration of vivianite recovery

The Phos4EU project focuses on scaling up the ViviMag process for extracting vivianite (hydrated iron(II) phosphate) from municipal wastewater treatment works. The ViviMag technology uses magnetic separation to extract vivianite from sewage liquors (see ESPP Technology Catalogue). The LIFE project will scale up from the existing pilot plant (automated 1 m3/h pilot) to representative scale  (half full scale, 9 m³/h digested sludge inflow) and test at waste water treatment plants (Roermond Netherlands and Burgos Spain). The project aims to recover at least 60% of the phosphorus in the input sludge and produce significant quantities of vivianite (c. 600 tonnes). This will be used for trials and market chain evaluation of possible uses of vivianite including in fertilisers, in fire safety, as a pigment, and as an input material for phosphorus recovery process tests (separation of phosphorus and iron to produce useable products, such as phosphoric acid or P4, iron chloride). CO2 emissions reductions will be calculated. The project partners are Limburg Water Board, Brabantse Delta Water Board, Acciona, Aquaminerals and STOWA, in cooperation with Kemira (ViviMag patent owner), Wetsus, Delft University, ICL, Rijn en IJssel Waterboard and Haskoning.

(half full scale, 9 m³/h digested sludge inflow) and test at waste water treatment plants (Roermond Netherlands and Burgos Spain). The project aims to recover at least 60% of the phosphorus in the input sludge and produce significant quantities of vivianite (c. 600 tonnes). This will be used for trials and market chain evaluation of possible uses of vivianite including in fertilisers, in fire safety, as a pigment, and as an input material for phosphorus recovery process tests (separation of phosphorus and iron to produce useable products, such as phosphoric acid or P4, iron chloride). CO2 emissions reductions will be calculated. The project partners are Limburg Water Board, Brabantse Delta Water Board, Acciona, Aquaminerals and STOWA, in cooperation with Kemira (ViviMag patent owner), Wetsus, Delft University, ICL, Rijn en IJssel Waterboard and Haskoning.

Phos4EU LIFE project (LIFE22-ENV-NL-LIFE Phos4EU – 101113877) 2025 – 2027, EU LIFE website project summary LINK.

Photo: 1 m3/h pilot ViviMag unit, 2023.

Policy

EU Battery Recycling Regulation to require phosphorus to be accounted

From 1st January 2030, phosphorus must be taken into account in calculating battery material recycling efficiency. ESPP suggests to go further and add phosphorus to the list of five elements with specific recycling targets. The final version of the Amending Regulation (adopted by the European Commission, pending publication) defining calculation methods for the battery recycling (fixing annexes to the EU Battery Recycling Regulation 2023/1542) specifies that the battery material recycling rate must take into account carbon and iron from cells and phosphorus. ESPP requested that this be modified from the draft submitted to public consultation in October 2024 (see ESPP eNews n°93) which left consideration of phosphorus voluntary (along with chlorine and sulphur). ESPP notes that the EU Battery Recycling Regulation 2023/1542 includes in Annex VI the obligation that labelling must indicate all EU Critical Raw Materials (CRMs) present at > 0.1% by weight. Phosphorus is an EU Critical Raw Material, with EU imports from Russia today a significant issue, and Lithium Iron Phosphate is today the dominant battery technology. ESPP therefore suggests that a delegated Regulation be considered to add phosphorus to the list of five elements with specific recycling targets (in Annex XII-C of 2023/1542).

Adopted Delegated Regulation “supplementing Regulation (EU) 2023/1542 … by establishing the methodology for calculation and verification of rates for recycling efficiency and recovery of materials from waste batteries, and the format for the documentation”, https://ec.europa.eu/info/law/better-regulation/have-your-say/initiatives/14265-Calculation-and-verification-methodology-of-rates-for-recycling-efficiency-and-recovery-of-materials-of-waste-batteries_en

EU Battery Recycling Regulation 2023/1542 https://eur-lex.europa.eu/eli/reg/2023/1542/oj/eng

ESPP letter to the European Commission on Battery Recycling Directive 31st December 2024 www.phosphorusplatform.eu/regulatory

EU phosphate supply: can Europe find enough P without Russian imports ?

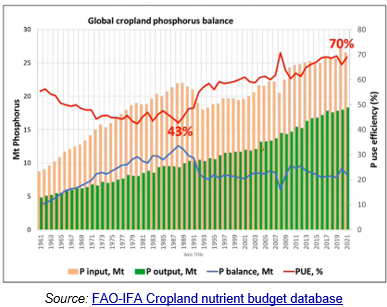

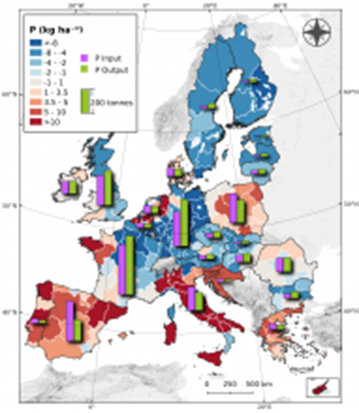

Expert analysis by Alberto Persona (Fertecon - S&P Global) shows EU P supply risks and dependency on imports from Russia, need to find and invest in new supply sources, joint projects in phosphate rock mining countries, recycling. The seven page analysis, following a suggestion by ESPP, is published here and fills information gaps as to date analysis has mainly concentrated on nitrogen fertiliser and potash supply and the EU nitrogen fertiliser industry crisis (caused by natural gas prices). The analysis notes the complexity of the phosphorus supply and use chains, including phosphate rock, phosphoric acid, P4 and derivatives (used in renewable energy and strategic industry sectors), fertilisers, animal feed phosphates, industrial phosphate uses, as well as P in animal feed and food products, manure and other organic wastes. International supply of phosphate rock, the raw material of all phosphorus value chains, is highly concentrated with five countries accounting for close to 80% of international trade: Jordan, Syria, Peru, Egypt. For phosphate fertilisers, the situation is similar, with again 5 countries accounting for about 80% of international trade: Morocco, Russia, the United States, Saudi Arabia, and China. EU phosphate imports overall decreased hugely 2021 – 2023, with the supply disruption and price increases following Russia’s invasion of Ukraine. Today around 25% of fertilizer imports and 30% of phosphate rock imports still come from Russia. Possible answers to the EU’s current high dependency on a small number of supply countries, including significantly Russia include: direct European investment in phosphate rock production and processing in other countries and development of new supply sources such as possible new mine projects in Europe and phosphorus recycling.

“The EU’s phosphate conundrum” (7 pages), April 2025, Alberto Persona, Associate Director of Fertilizer Analytics, Fertecon - S&P Global Commodity Insights here https://www.phosphorusplatform.eu/downloads

EU Clean Industrial Deal (CID): decarbonisation, circularity

Commission flags fertilisers as a showcase for low-carbon and recycled nutrients reducing import dependencies, emissions and prices for farmers. CID may open door for actions on P-recycling, P4, bioeconomy, investments.

The fertilisers industry is flagged as an illustration of the potential of the CID, with low-carbon and recycled nutrient fertilisers (page 16).

The European Commission’s Clean Industrial Deal (CID) aims to make decarbonisation a driver for economic growth, quality jobs and business resilience, by removing dependency on energy prices and imported resources, and in parallel circularity, to maximise resource use and reduce import dependencies, making the EU more competitive and resilient. Sectorial plans will be developed for automotive, steel and metals, chemicals (adoption late 2025), transport and the bioeconomy. Significant funds will be mobilised for investments in clean transition, decarbonisation and circularity.

Specific policies announced include:

- Introducing sustainability, resilience and ‘made in Europe’ criteria in Public Procurement (see also: “ESPP input submitted: Evaluation of public procurement directives” in ESPP eNews n°95),

- Trans-Regional Circularity Hubs

- Possible company joint purchasing for Critical Raw Materials (phosphates, P4), in an EU Critical Raw Materials Centre,

- Incentivise diversion from landfill to recycling and more effective separative collection,

- Work with Member States to green tax systems,

- Facilitate trade and investment partnerships (ESPP comment: could be relevant for phosphate and phosphorus chemicals?),

- Support investments in green energies, electricity grid and storage

The CID includes (page 14) indications concerning the Circular Economy Act planned for 2026. This will aim to:

- “enable the free movement of circular products, secondary raw materials and waste, foster a higher supply of high quality recyclates and stimulate demand for secondary materials and circular products while bringing down feedstock costs”,

- “harmonise “end of waste” criteria to facilitate the transition from waste to valuable secondary raw materials”,

- “simplify, digitalise and expand in a targeted manner extended producer responsibility”

- “boost demand through criteria for public procurement”

- “mandate the use of new raw material sources like recycled and bio-based materials to substitute, for example, virgin fossil materials in plastics”.

European Commission “Clean Industrial Deal. A plan for EU competitiveness and decarbonisation”, 26th February 2025 https://commission.europa.eu/topics/eu-competitiveness/clean-industrial-deal_en

EU Green Deal progress assessment

European Commission 2025 analysis of Green Deal underlines challenges to deliver the -50% nutrient loss reduction target. The 150 page document by the Commission’s Joint Research Centre (JRC) analyses progress towards achieving Green Deal targets and relevant policies by seven thematic areas, including ‘Circular Economy’ and ‘Greening the CAP / Farm-to-Fork’ and covers a total 154 targets (from 44 policy documents), some binding, others non-binding. Progress is considered on-track for nearly two thirds of targets, whereas around one third will require accelerated effort and 10% are in reverse or stagnation. Nutrient loss reduction is considered as ‘requiring acceleration’ despite the 2005-2020 trend being “rather stagnant” (indicator: nitrates in groundwater, page 87). The Key Messages for the CAP thematic area state: “Meeting reduction targets for … nutrient losses remains challenging and requires acceleration. The consumption footprint of food showed an increasing trend, primarily driven by animal-based products …The EU food system contributed to the transgression of some planetary boundaries.” Nutrient recovery and more efficient fertiliser application are also cited under the thematic area ‘Zero Pollution Ambition’, with nutrient loss reductions are identified as posing challenges to soil health strategy targets, and nutrient losses to water are again flagged in the Key Messages for this thematic area.

“Delivering the Green Deal. Progress towards targets”, European Commission (JRC) 2025, 150 pages, ISBN 978-92-68-23180-7, https://dx.doi.org/10.2760/3105205

Circular Economy Act

EURIC (recycling industry) priorities

The confederation calls to integrate climate and circularity policies. Proposals include facilitating End-of-Waste, distinguishing between raw waste and processed secondary raw materials, recycled target contents for products. Although EURIC is little concerned by the nutrient circular economy and organics recycling, EURIC’s priorities roadmap 2024-2029 includes a number of proposals relevant to nutrients in the future EU Circular Economy Act:

- Accelerate EU End-of-Waste criteria, with fast-track where a value chain agrees on proposed criteria,

- Mutual Recognition (i.e. by other Member States) of “National” End-of-Waste for non-hazardous wastes,

- Distinguish between unprocessed waste and quality recycled secondary materials, to enable free trade of the latter,

- Facilitate waste shipments,

- Address at source contaminants and chemicals susceptible to be an obstacle to recycling and protect the EU market from imports of products which are not compliant,

- Lower VAT for recycled products,

- Set recycled content targets (“quotas”) for products (EURIC refers to metals, tyres and textiles),

- Facilitate innovation and testing.

“4 priorities for recyclers 2024-2029. Bridging policy ambition with industrial reality”, EURIC, the European Recycling Industries’ Confederation, 2024, 8 pages https://euric.org/images/Position-papers/EuRIC_Priorities_2024-2029.pdf

Italians call for ambitious Circular Economy Act

Confindustria (Italy industry federation) and Italian MEPs call for simplification and a technology neutral approach to support recycling technologies to develop circularity in parallel with climate goals. An informal meeting in the European Parliament was hosted by MEP Massimiliano Saini (EPP), with Cofindustria, Gilberto Pichetto Fratin, Italy’s Minister for the Environment, Antonio Decaro MEP (S&D), the European Commission and a number of industry representatives. Cofindustria has published a report on Circular Economy strategies, making recommendations including

- Coordinate energy transition, sustainability, supply security and circular economy policies,

- Harmonise and simplify regulations (e.g. EcoDesign, Green Claims, waste …),

- Simplify waste management authorisation procedures and rationalise End-of-Waste,

- Promote circularity through Public Procurement and fiscal and financial measures,

- Remove obstacles and streamline site permitting,

- Rationalise End-of-Waste,

- Simplify regulation for research and innovation.

“Informal debate in European Parliament shows early industry demands for Circular Economy Act”, EuroNews, 17th March 2025 HERE

“Circular Economy: industrial strategies and prospects”, Confindustria, full report in Italian 300 pages, summary in English 30 pages, March 2025 https://www.confindustria.it//home/policy/position-paper/dettaglio/rapporto-economia-circolare

Netherlands associations proposals for Circular Economy and End-of-Waste

Based on wide consultation of stakeholders, proposals are to enable currently complex End-of-Waste by ‘Voluntary Certification’ defined between supplier and buyer, which can then be translated into legal criteria. The proposals are developed by consultant EcoMatters for Invest-NL, a state-owned organisation which finances entrepreneurs, and Groene Chimie Nieuwe Economie, a platform to facilitate sustainable transition in chemicals production. Proposals include:

- Develop End-of-Waste ‘Self Declaration’,

- Develop EU recognition of national End-of-Waste rulings,

- Enable national End-of-Waste rulings to justify other End-of-Waste claims,

- Clarify End-of-Waste requirements, in particular concerning health and environment safety,

- Enable industry-led certification schemes for specific waste streams, recycling technologies or applications, when End-of-Waste criteria do not exist, with legal recognition, where possible using existing certification systems and organisations,

- Develop EU End-of-Waste criteria, in particular for plastics and for bio-based waste streams,

- Providing a single point of contact,

- Develop guidance, link to product legislation.

“End of Waste White Paper” (44 pages, in English), Invest-NL, Groene Chimie Nieuwe Economie, EcoMatters, 05_04_2023 https://www.invest-nl.nl/business-development/publicaties/end-of-waste?lang=en

“Eeinde-Abvalstatus Pplossingstrategie & Plan” (End of Waste Status Solution Strategy), (16 pages, in Dutch,, with 2 page English summary), Invest-NL, Groene Chimie Nieuwe Economie, BinGo Results, July 2023 https://www.invest-nl.nl/business-development/publicaties/end-of-waste?lang=en

Nutrient recycling

CleanTeQ Water delivering first PHOSPHIX® ion-exchange P-recovery plant

Full-scale (90 m3/h) PHOSPHIX unit will treat discharge from an MBR (membrane bio-reactor) treating wastewater for an industrial client in Ireland. Detailed design phase is underway and plant is expected to be operational in early 2026, recovering up over 100 tonnes per year of hydroxyapatite rich sludge (dry mass basis) per year (c. 15 t/y of phosphorus – P). This follows successful on-site testing of a pilot unit operating at 8 l/h inflow. PHOSPHIX® was developed by CleanTeQ Water (Australia) and is commercialised and implemented in Ireland through a partnership with ENVA, a provider of waste management and resource recovery solutions. The PHOSPHIX® process uses selective ion exchange to achieve P-removal to <0.1 mgPortho/l. Sodium hydroxide and sodium chloride are used for ion exchange resin regeneration then lime is used to precipitate calcium phosphate (hydroxyapatite) for P-recovery, and the P-depleted solution can be recycled back for further use for regeneration, so minimising reagent consumption. For this project, the MBR inflow to the PHOSPHIX® unit has soluble phosphorus levels up to 20 mgPortho/l, moderate levels of organics (TOC < 10 mg/L) and low suspended solids (TSS < 5 mg/L), but contains significant levels of ions such as 1,500 mg/l SO4, 600 – 800 mg/l HCO3, and 500 mg/l Cl. The selective phosphorus removal has shown not to be significantly impacted by these ions.

See ESPP Nutrient Recovery Technology Catalogue https://www.phosphorusplatform.eu/techcatalogue

“Clean TeQ Water Awarded a Contract of over AU$11m for a PHOSPHIX® Plant in Ireland” [c. 7 million €], 15th November 2024 https://www.cleanteqwater.com/news/clean-teq-water-awarded-a-contract-of-over-au11m-for-a-phosphix-plant-in-ireland/

A poster outlining the project will be presented at the IWA Nutrient Removal and Recovery Conference, the Netherlands, in May, and a full paper will be presented in May Australia’s water conference OzWater

Stercore manure pyrolysis project validated

EU-funded expert’s opinion should enable STERCORE’s manure pyrolysis to start construction in The Netherlands, aiming to process c. 400 000 t/y manure and farm wastes to biochar, methane and food-grade CO2. The plant construction in Emmen, The Netherlands, was announced in 2020 but has been delayed by a court case brought by an environmental NGO Milieudefensie Westerveld. This was finally resolved by the Netherlands High Court declaring Milieudefensie’s appeal unfounded in 2023. EU Green Assist has funded an expert review of Stercore’s business plan and technical documentation, following a request by one of the company's equity funders. The EU’s Green Assist (Green Advisory Service for Sustainable Investments Support, InvestEU and LIFE) can fund free advisory services by accredited experts, to project promoters, financial institutions or other project partners, with the aim of facilitating green investment projects. The Green Assist funded opinion for Stercore and the resolution of the legal challenge should now allow the project to go ahead. The plant will include composting to pre-dry and sanitise the input materials, pyrolysis, treatment of syngas to purified methane (objective 23 million m3/y), recovery of purified liquified CO2, combining of the biochar with organic materials and mineral nutrients to produce tailor-made fertilisers.

Stercore: See ESPP Nutrient Recovery Technology Catalogue https://www.phosphorusplatform.eu/techcatalogue

“Green Assist: the Green Advisory Service for Sustainable Investments Support” LINK.

EU CINEA press release “Green Assist: Producing sustainable end products from renewable raw materials”, 28th January 2025

Stercore press release “STERCORE has been fully vindicated by the Council of State”, 12th October 2023

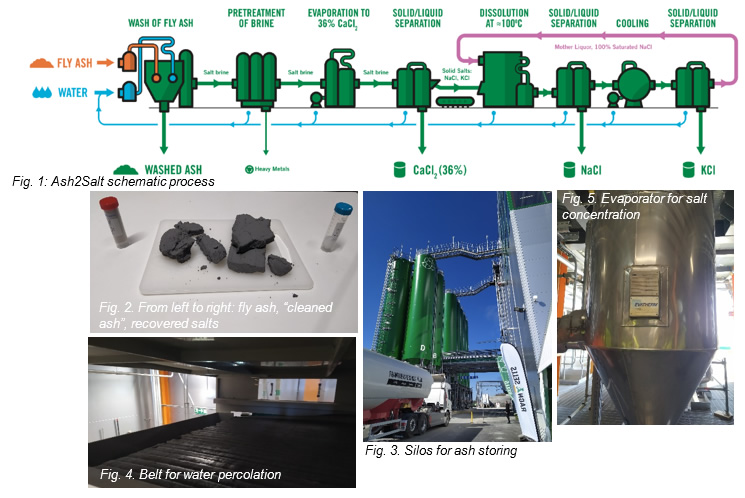

EasyMining confirms funding for first Ash2Phos plant

The Saxony-Anhalt Environment Ministry has confirmed 27 million € funding for the first full-scale Ash2Phos P-recovery plant at Schkopau near Leipzig, to process 30 000 t/y of sewage sludge incineration ash (see ESPP eNews n°62). The Ash2Phos process leaches more than 90% of the phosphorus out of ash using hydrochloric acid, then separates iron, aluminium and heavy metals by a series of dissolution and precipitation steps, resulting in a clean calcium phosphate product of animal food quality. A second 30 000 t-ash/y plant is under permitting at Helsingborg, Sweden (see ESPP Nutrient Recovery Technology Catalogue). The Schkopau plant is a joint venture with Gelsenwasser AG, one of Germany’s largest utility companies operating mainly in the Ruhr, Muensterland, lower Rhein and Eastern Westphalia regions. The Minister of the Environment for Saxony-Anhalt, Armin Willingmann, commented: “With the establishment of this highly innovative phosphorus recovery plant, Saxony-Anhalt can once again make a name for itself as a state of future technologies. Phosphorus is a critical raw material on which our agriculture in particular depends on. Recovering the raw material could also make an important contribution to protecting our environment and our natural resources.”

“Saxony-Anhalt funds innovative phosphorus recovery plant in Schkopau, Germany”, EasyMining News, 17th February 2025.

Research

Food phosphate additives widespread in US foods

Labels suggest that phosphate food additives are present in over half of 40 000 processed food products from leading US manufacturers. Suggestions of health risks are however unclear. Analysis of labels of processed food products from the 25 leading US food product companies conclude that one or more phosphorus-containing food additives are present in 56% of products representing 52% of (relevant) sales (the sales of these P-additive containing products represent some 250 billion US$ revenue for these 25 companies). The most frequently identified additive (32%) is however lecithin, which is not an inorganic phosphate food additive, but is a mixture of extracted plant phospholipids. Also, nearly one third of the products containing P-additives were beverages (probably largely phosphoric acid used in fizzy drinks). The authors conclude that this shows widespread population exposure in the USA to P food additives, neglecting to point out that this is only relevant for people significantly consuming processed food products. They note that this study does not allow quantification of contribution of P food additives to dietary P intake. Despite this, the paper’s abstract states that “Phosphate additives have more rapid/efficient absorption than naturally occurring dietary phosphate and … greater contribution to total phosphorus intake.”. This is misleading and to ESPP’s understanding wrong: it ignores that the paper’s data suggests that 32% of P-additives are lecithin, plus 10% P-modified starch, which are not inorganic and not better absorbed. There is no evidence in the paper to support the surprising statement that food additive P in diets is higher than natural diet P. Indeed, the paper’s cited references include Fulgoni et al. 2021 who concluded that food additive P is less than one fifth of total P intake and decreasing (see summary in ESPP eNews n°70). The paper also suggests that phosphate food additive intake is linked to health problems in the general population (not kidney patients), but the cited references for this seem limited and unclear, in some cases making a link between ultraprocessed food consumption and kidney decline (Cai et al, Netherlands, 2022) without evidence that this is related to phosphorus in the ultraprocessed foods, in other cases based on only one high phosphate dose (Volk et al. 2022). To ESPP’s understanding, there is evidence relating increased (baseline) blood phosphate levels to health problems (in particular cardio vascular disease CVD) in healthy human populations (not kidney patients), as well as animal studies showing such effects and known potential physiological mechanisms (calcium phosphate precipitation leading to artery hardening, hormone changes), but no clear evidence that increased diet phosphorus leads to increased blood phosphorus (except in the hours after the P intake) in persons whose kidneys are functioning normally (see discussion of Cooke (IFAC) 2017 in ESPP eNews n°16). One cited recent study, however, based on FFQ (food frequency questionnaire) and urine analysis of nearly 4 000 Jackson Heart Study participants, concludes a link between estimated food phosphate intake (but not natural diet P) and kidney function (Duong et al. 2022)

“Phosphate-based additives in processed foods: is excess exposure a cause for concern? A cross-sectional examination of the United States packaged food supply”, E. Dunford & M. Calvo, Am J Clin Nutr, 2025, 121, 873-881, DOI.

“Industrial Use of Phosphate Food Additives: A Mechanism Linking Ultra-Processed Food Intake to Cardiorenal Disease Risk?” M. Calvo, E. Dunford & J. Uribarri, Nutrients 2023, 15, 3510, DOI.

“Bioavailability of phosphorus and kidney function in the Jackson Heart Study”, C. Duong et al., Am J Clin Nutr 2022, 116, 541–550, DOI.

Stay informed

SCOPE Newsletter: www.phosphorusplatform.eu/SCOPEnewsletter eNews newsletter: www.phosphorusplatform.eu/eNewshome

If you do not already receive ESPP’s SCOPE Newsletter and eNews (same emailing list), subscribe at www.phosphorusplatform.eu/subscribe

LinkedIn: https://www.linkedin.com/company/phosphorusplatform

Slideshare presentations: https://www.slideshare.net/phosphorusplatform

YouTube https://www.youtube.com/user/phosphorusplatform

ESPP members

Newsletter about nutrient stewardship - European Sustainable Phosphorus Platform (ESPP)

Please subscribe www.phosphorusplatform.eu/Subscribe

Link to www.phosphorusplatform.eu/eNews095

Download as PDF

Events

10-12 June 2025, Bergen, Norway: nutrients in aquaculture and fisheries workshop

9th April: Flashphos demonstration of sludge drying for P4-recovery

17-18 June 2025: European Wastewater Management Conference

Consultations

Open: EU Fertilising Products Regulation – audit frequencies

Open: Evaluation of EFSA

Open: US EPA consultation on PFAS in sewage sludge and water

Open: EU consultation on simplification of sustainability reporting and taxonomy

Open: EU consultation on next EU budget framework

Closed: EU call for evidence on green transformation for industry and livestock

ESPP input submitted: EU public consultation on water resilience

ESPP input submitted: Evaluation of public procurement directives

ESPP input submitted: UK Parliament Inquiry on Nitrogen

ESPP input submitted: ash-recovered phosphates in Organic Farming

Policy

European Commission “Vision for Agriculture and Food”

State of Europe’s waters

European Commission Report on Water Framework Directive Implementation

Nutrient recovery

UKWIR report: valorisation of potable water treatment sludges

UN FAO report on nitrogen in agri-food systems

Phosphorus, food and health

Mouse maternal high phosphorus diet impacts offspring mineral metabolism and growth

Mouse high P diet leads to heart disease risks

Sustainable development of the food & beverage industry

Commiserations

Stay informed

ESPP members

Events

10-12 June 2025, Bergen, Norway: nutrients in aquaculture and fisheries workshop

ESPP workshop, with partners in Norway and UNEP uPcycle, on nutrient management in aquaculture: fish feed, seafood processing and fish sludge valorisation, Norway & online, 10-12 June 2025, covering nutrient flows, environmental best practice, phosphorus recycling, regulatory challenges. The workshop will contribute to the United Nations (UNEP) project uPcycle, leading to a UNEP white paper on phosphorus sustainability in aquaculture. Site visits to in-sea fish farm with sludge recovery, research installations, fish sludge processing.

A few slots are still available for presentations of fish and aquaculture industry nutrient sustainability actions, fish feed industry, fish sludge nutrient recycling. Programme: https://phosphorusplatform.eu/AquacultureFisheries

9th April: Flashphos demonstration of sludge drying for P4-recovery

Demonstration of pilot sewage sludge dryer – grinder (input 50 kg/h wet sewage sludge), presentation of Flashphos P4 recovery project and operating experience in sludge processing to date. Stuttgart and online. Discussion with experts about sludge treatment, P-recovery and challenges of novel recycling approaches. The Flashphos (EU Horizon 2020) aims to demonstrate recovery of white phosphorus from dried sewage sludge at 250 kg/h pilot scale (see ESPP eNews n°94). The preparation of the sewage sludge, to a dry fine, homogenous powder, is key to the process, to allow fast gasification in the FlashReactor using the organic carbon in the sewage sludge for heat energy. This prepares the minerals for P4 release with a reducing agent (coke or similar) in the Refiner.

Flashphos (EU Horizon 2020 R&D project, 2021-2026) https://flashphos-project.eu

Demonstration event organised by University of Stuttgart, Buss-SMS-Canzler GmbH and Steinbeis Europa Zentrum. 9th April 2025, 9h30 – 16h15, Stuttgart, Germany, and online. In English. Free. Agenda, registration: https://eveeno.com/flashphos

17-18 June 2025: European Wastewater Management Conference

ESPP will speak at Europe’s leading conference for wastewater treatment operational experience, solutions and technologies, Telford International Centre, UK, 17-18 June 2025.

Early bird registration to 11th April 2025 https://ewwmconference.com/

Consultations

Open: EU Fertilising Products Regulation – audit frequencies

EU public consultation, open to 27th March 2025, on change to audit requirements for recovered materials (D1), to avoid excessive audit frequency for high volumes, and change to ammonium nitrate fertilisers conformity assessment requirements (explosive potential).

“EU fertilising products - amendment of conformity assessment procedures”, public consultation, open to 27th March 2025 https://ec.europa.eu/info/law/better-regulation/have-your-say/initiatives/14548-EU-fertilising-products-amendment-of-conformity-assessment-procedures_en

Open: Evaluation of EFSA

Public consultation open to 1st April 2025 for the evaluation of EFSA (European Food Safety Agency).

See ESPP eNews n°94.

Questionnaire plus possibility to input general or specific comments (max. 5 000 characters) and/or upload documents or input papers.

“European Food Safety Authority – evaluation of performance 2017-2024”, EU public consultation open to 1st April 2025 https://ec.europa.eu/info/law/better-regulation/have-your-say/initiatives/14068-European-Food-Safety-Authority-evaluation-of-performance-2017-2024_en

Open: US EPA consultation on PFAS in sewage sludge and water

Public consultation open to 16th and 25th April 2025 (respectively) on US EPA draft risk assessment of PFOA and PFOS in sewage sludge used in agriculture, forestry or landfilled and draft water quality limits for PFOA and PFAS. PFOA (perfluoroocatnoic acid) and PFOS (perfluorooctane sulfonic acid) are both part of the PFAS family (perfluoroalkyl and polyfluoroalkyl substances). The conclusions will inform future US regulatory action under the Clean Water Act. The US EPA classified both PFOA and PFOS as likely carcinogenic in 2024 and concluded that they can have a range of other impacts (see here PFOA and PFOS). The draft risk assessment concludes that land use of sewage sludge (e.g. digested or composted sludge) could result in human health risks, from PFOA and PFOS, exceeeding acceptable thresholds for both cancer and non-cancer risks (based on 40 annual applications at 10 tDM/ha/y, the median US sewage sludge application rate). Human health risk levels were exceeded in scenerios of application to grazing land or for food with risks resulting from PFAS levels in e.g. drinking water, fish, beef, milk, eggs, fruit, vegetables. In some cases, risks levels were exceeded with only one application of sewage sludge containing 1 ppb PFAS. Risk estimates for some human intake pathways can exceed EPA acceptable thresholds by “several orders of magnitude", including via drinking water, contaminated milk from grazing, eating fish or fruit and vegetables. The EPA underlines the need for prevention at source: monitoring of PFAS in sewage works and pre-treatment of industrial sources.

“Draft Sewage Sludge Risk Assessment for Perfluorooctanoic Acid (PFOA) and Perfluorooctane Sulfonic Acid (PFOS)”, US EPA public consultations open to 16th and 25th April 2025 https://www.epa.gov/biosolids/draft-sewage-sludge-risk-assessment-perfluorooctanoic-acid-pfoa-and-perfluorooctane

Open: EU consultation on simplification of sustainability reporting and taxonomy

Public consultations on modifications to EU Sustainability Reporting Standards and to the EU Taxonomy Regulation annexes, as part of the Commission’s ‘Omnibus’ simplification package. This package announces simplifications and wider exemptions for the CSRD (Corporate Sustainability Reporting Directive) and the EU Taxonomy, CBAM (Carbon Border Adjustment Mechanism) and due diligence. The Commission estimates that the proposed simplifications will bring over 6 billion € reduction in administrative costs and mobilise 50 billion € public and private investment. It is part of the Commission’s commitment to reduce administrative burdens by 25% and by 35% for SMEs. Key points include:

- Removing 80% of companies from CSRD, leaving only the largest companies

- Ensuring that larger companies’ reporting obligations and due diligence do not burden SMEs in the value chain

- Simplify the DSNH (Do NO Significant Harm) criteria

- Exempt smaller importers (90% of companies) from CBAM

- Simplify calculation of embedded emissions

- Extend implementation deadlines

- Various other simplification, coherence and harmonisation changes

European Commission ‘Omnibus Package’ announcement 26th February 2025 “Commission simplifies rules on sustainability and EU Investments” https://ec.europa.eu/commission/presscorner/detail/en/ip_25_614?link_id=a2a47574-5401-4cc8-95c7-0c429f73aeed

EFRAG public consultation (under mandate from the European Commission) on simplification of the European Sustainability Reporting Standards (ESRS) open to 6th May 2025 https://survey.alchemer.eu/s3/90824354/ESRS-Set-1-revision-Questionnaire-for-public-feedback

EU public consultation, open to 26th March 2025, on technical modifications to EU Taxonomy Regulation annexes https://ec.europa.eu/info/law/better-regulation/have-your-say/initiatives/14546-Taxonomy-Delegated-Acts-amendments-to-make-reporting-simpler-and-more-cost-effective-for-companies_en

Open: EU consultation on next EU budget framework

EU public consultation, open to 6th May 2025, on post-2027 Multiannual Financial Framework (MFF), to inform the architecture of the EU budget for the next 5-10 years. Six different consultations are open, addressing EU policies on Member States and Regions (inc. agriculture), external action, education / civil society, civil protection and crisis response, single market, budget performance.

On policies with Member States and Regions, the consultation is a short questionnaire (11 questions) asks for opinions on relative importance of challenges from transport and security to decarbonising the economy (one of the 22 options proposed is “Maximising the potential of the circular economy”), obstacles and effectiveness of EU funding, specific objectives of different policies (Cohesion, Agriculture = CAP, fisheries & marine, transport). As well as the short questionnaire, it is possible to submit a free document or position paper.

The consultation questionnaire on ‘budget performance’ addresses in particular gender equality and climate & environment (e.g. “do no harm” principle).

“EU’s next long-term budget (MFF) – performance of the EU budget”, public consultation, open to 6th May 2025 https://ec.europa.eu/info/law/better-regulation/have-your-say/initiatives/14526-EUs-next-long-term-budget-MFF-performance-of-the-EU-budget_en

Closed: EU call for evidence on green transformation for industry and livestock

Non-public call for input, data or examples on green transformation pathways, plans and investment needs to reduce greenhouse emissions and increase circularity of IED installations (industrial sites, large livestock farms) Two studies are launched by the European Commission to evaluate the investments needed by different industries (covered by IED 2010/75, as updated by Directive 2024/1785) “to achieve carbon neutrality, zero pollution and circular economy objectives”, and to support definition of “transformation plans” for these industries. IED covers both industrial sites subject to operation permitting (IED = “Industrial Emissions Directive”) and also, since 2024, large livestock farms – a total of around 75 000 industrial and livestock installations across Europe. Information requested includes defining transformation pathways for IED covered industries (including intensive livestock), costs of transformation, content of transformation plans, proposed benchmarks and targets (may be linked to BAT), available technologies, issues of access to funding.

If you are interested, please contact ESPP (member of the EU IED Forum) and we will send you the consultation documents, including contacts for submitting information, or you can send information to ESPP and we will forward . Formal deadline closed 14th March.

ESPP input submitted: EU public consultation on water resilience

ESPP input underlines the importance of Circular Economy (recycling of water and nutrients) in improving water resilience, and that climate change will increase needs for both nutrients and irrigation water. Climate change is expected to enhance nutrient mineralisation, so increasing nutrient losses, and increase crop nutrient uptake due to increased atmospheric CO2, thus directly linking water resilience to nutrient management and fertiliser use. ESPP suggests that the EU Water Resilience Strategy should take into account the need to reduce EU dependency on imported fertilisers, the importance of reducing pollutants at source, the Critical Raw Materials Act, the European Commission’s announced EU Circular Economy Act and the recast Urban Waste Water Treatment Directive 2024/3019 which refers to water resilience in Recital 29 and art. 15 and requires the definition of Phosphorus Reuse and Recycling Rates in art. 20. Concerning pollution at source, ESPP states that this is a key prerequisite for water reuse, for nutrient recycling and for circularity of other materials recovered from waste water treatment. Industrial chemicals which pose obstacles to circularity or to water reuse should be phased out rapidly, with authorisation only for very limited authorisations for limited essential uses where loss to the environment is not expected until alternatives can be developed. In particular, the restriction of PFAS announced in 2020 (COM(2020)667) should be implemented rapidly, banning all non-essential uses.

“European Water Resilience Strategy”, public consultation, closed 4th March 2025. https://ec.europa.eu/info/law/better-regulation/have-your-say/initiatives/14491-European-Water-Resilience-Strategy_en

ESPP input submitted (1 page): www.phosphorusplatform.eu/regulatory

ESPP input submitted: Evaluation of public procurement directives

ESPP input that the EU’s three public procurement Directives should be updated to better facilitate and incite environmental objectives in public purchasing selection, in particular to support the circular economy, in coherence with the Commission’s ‘Vision for Agriculture and Food” COM2025(75) which fixes the aim of strengthening the role of Public Procurement with a “best value” approach to reward quality and sustainability, including certified Organic products and short food supply chains, and with the Enrico Letta report April 2024 “Much more than a market - Speed, Security, Solidarity – Empowering the Single Market to deliver a sustainable future and prosperity for all EU Citizens”. ESPP suggests that consideration of environmental aspects be no longer an option in Public Procurement, subjecto to difficult conditions, but should required wherever feasible, including taking into account circularity, use of secondary raw materials and EU Critical Raw Materials, as well as the bioeconomy and short supply chains, local, regional and EU production.

See ESPP eNews n°94.

“Public procurement directives – evaluation”, EU public consultation, closed 7th March 2025 https://ec.europa.eu/info/law/better-regulation/have-your-say/initiatives/14427-Public-procurement-directives-evaluation_en

ESPP input submitted (1 page): www.phosphorusplatform.eu/regulatory

ESPP input submitted: UK Parliament Inquiry on Nitrogen

ESPP input underlined synergies between reducing nitrogen losses, recycling nitrogen and development of renewable manure biogas, as well as the need to recycle N to reduce dependency on imported fertiliser and natural gas. ESPP underlined that reducing nutrient losses is signed into the United Nations COP15 Kunming-Montreal convention Global Biodiversity Framework, December 2022 (ESPP eNews n°74) and that reducing N losses can be combined with N-recovery (e.g. ammonia stripping/scrubbing from manure offgases) or with improved recycling of N in wastes (reduce N losses from manure or digestates during field application, e.g. by acidification of manure or by injection into soil rather than surface spreading – so increasing the effective recycling rate). Input summarised conclusions of the two international workshops on nitrogen recycling organised by ESPP in 2023 (SCOPE Newsletters n°s 145 and 148) and the operational summary of literature relevant to N-recycling in SCOPE Newsletter n° 147. ESPP also underlined the importance of ensuring that recovered nutrients find a market, commercially (competition with ‘virgin’ mineral nutrients), in regulations and as regards product quality. See ESPP’s proposals (developed with wide stakeholder consultation) for policies to facilitate nutrient circularity (input to the upcoming EU Circular Economy Act) and for “market pull” for recycled nutrients.

UK Parliament (House of Lords Environment and Climate Change Committee), Call for Evidence on Nitrogen, closed 7th March 2025 https://committees.parliament.uk/committee/515/environment-and-climate-change-committee/news/205099/environment-and-climate-change-committee-launches-new-inquiry-into-nitrogen/

“UKWIR provides evidence for the House of Lords Environment and Climate Change Committee Nitrogen Inquiry, 14th March 2025 https://ukwir.org/hol-0

ESPP input submitted (4 pages): www.phosphorusplatform.eu/regulatory

ESPP input submitted: ash-recovered phosphates in Organic Farming

ESPP input to EU consultation on use of calcium phosphates from sewage sludge ash in certified Organic Farming: ESPP supported the proposed authorisation and requested consideration of other recycled nutrient materials.

ESPP welcomed the proposed authorisation of calcium phosphates derived from sewage sludge ash as fertiliser in Organic Farming, based on the positive EGTOP Opinion of March 2024, and requested that this modification of the Organic Farming inputs regulation 2021/1165 be implemented rapidly, with the text as proposed. ESPP noted that the proposal contributes positively to sustainability and productivity of Organic Farming, to stewardship of the EU Critical Raw Material “Phosphate Rock” (Critical Raw Materials Act 2024/1252) and to EU Circular Economy objectives.

In order to ensure safety and farmer confidence, ESPP supported the proposal that the recovered calcium phosphate should respect the EU Fertilising Products Regulation quality criteria and contaminant limits.

ESPP noted that the wording “calcium phosphate” can mean any inorganic compound (derived from sewage sludge incineration ash) consisting of calcium, phosphorus, hydrogen and oxygen, e.g. monocalcium phosphate, dicalcium phosphate, octacalcium phosphate, amorphous calcium phosphates, hydroxyapatite, single super phosphate, triple super phosphate.

ESPP requested future consideration, for Organic Farming, of calcium phosphates recovered from ash from animal by-products and of “Calcined Phosphates” from sewage (EGTOP gave a positive opinion in 2016 recommending authorisation for use in Organic Farming). ESPP suggested that EGTOP consider all ash-derived phosphates respecting the EU FPR (PFC1 mineral phosphate fertiliser criteria and CMC13 criteria, possibly subject to other specific Organic Farming criteria such as exclusion of manure from ‘factory farming’, solubility criteria … ). This would avoid the current one-by-one assessments which are slow and time-consuming.

“Organic production – amended list of authorised products and substances”, EU public consultation closed 4th March 2025. https://ec.europa.eu/info/law/better-regulation/have-your-say/initiatives/14024-Organic-production-amended-list-of-authorised-products-and-substances_en

ESPP input to public consultations: www.phosphorusplatform.eu/regulatory

Policy

European Commission “Vision for Agriculture and Food”

Strategy document aims for an “attractive, competitive, resilient, future-orientated and fair” agri-food system, including climate, carbon credits, nature and environment protection, nutrient management and nutrient circularity. The vision aims to achieve “strategic autonomy and food sovereignty” and to reconcile food security, food safety, farm incomes and climate and environmental objectives (including soil health, clean water and water scarcity, biodiversity), whilst emphasising simplification, competitiveness and digitalisation. Vulnerabilities identified include dependency on imports for fertilisers, feed and energy, in particular for high-protein feeds and fertilisers. Fertilisers are identified as “essential for food production and security”, and pose price stability problems for farmers, with the EU increasingly dependent on a small number of import supplying countries. Support is necessary for low-carbon fertilisers and recycled nutrients. Farm nutrient management and nutrient circularity are cited objectives. The bioeconomy, carbon farming, nature credits and renewable energy production are seen as key areas for innovation and additional sources of income for farmers.

The vision indicates that CAP (Common Agricultural Policies) currently account for 23% of average EU farm income and confirms the CAP as the key tool for taking forward policy objectives.

ESPP comment: as often with such strategy documents, there is a feeling that everything has been included to please everyone (and that ESPP has selectively cited a few paragraphs on nutrients and fertilisers found somewhere in the 27 pages). However, the following do appear as announced actions (rather than ‘wishes’), whilst underlining that one-size-fits-all solutions are not applicable to farming across Europe and that actions must therefore be largely delegated to national, regional and local authorities:

- Carbon credits

- Nature credits

- A voluntary on-farm environmental benchmarking system “On-Farm Sustainability Compass”

- CAP reduction of farm subsidy disparities (capping for big farms), focus on young farmers and on farming in areas of “natural constraints”. CAP to focus on incentives and investments, rather than “conditions”

- Alignment of standards for imported products, to ensure fair competitiveness of EU farms, e.g. presence of pesticides banned in the EU, animal welfare conditions

- Support for EU fertiliser production

- Support for low-carbon fertilisers and recycled nutrients, in particular appropriately used and treated digestates

- Reinforcement of agricultural crisis funding mechanisms (European Food Security Crisis Mechanism, agricultural reserve)

- Strengthening the role of Public Procurement with a “best value” approach to reward quality and sustainability, including certified Organic products and short food supply chains

- Work stream on “excellence livestock production chain” addressing global competition, imports/exports, climate and environmental footprint, maintenance of extensive grasslands (valuable for climate, landscape, biodiversity), sustainable production models

- Addressing nutrient pollution hotspots with territorial approaches to management and control of livestock farming and support for extensification, in the context of the evaluation of the Nitrates Directive due end 2025.

“Commission presents its roadmap for a thriving EU farming and agri-food sector”, press release, 19th February 2025 and European Commission Communication COM 2025(75) – 27 pages “A Vision for Agriculture and Food. Shaping together an attractive farming and agri-food sector for future generations” here.

State of Europe’s waters

The European Environment Agency (EEA) report on the state of waters 2024 says the EU needs to accelerate actions to improve water resilience and water quality. Less than 30% of waters achieve good chemical status, with little improvement over the last decade. Climate change will accentuate pressures on water resources. Member States report that the most significant pressure on both surface and groundwater resources is agriculture: intensive use of nutrients and pesticides. Diffuse agricultural pollution, in particular pesticides and nutrients, is important in impacting water quality, as are long-lived pollutants, in particular mercury and brominated flame retardants (each of which alone are responsible for nearly half of water body quality failures – one parameter failure = quality failure). Agriculture is considered more than twice as impacting on surface waters than wastewater discharges, and also as having high impact on groundwaters. Agricultural nutrient losses (leaching/run off and in soil erosion) are more than four times wastewater discharge for nitrogen and more than two times for phosphorus. The EEA notes that “high concentrations of nitrogen and phosphorus and contamination by organic substances from manure and sewage continue to have serious ecological effects in Europe. These include toxic algal blooms and oxygen depletion”. Nearly 20% of surface waters failed nutrient quality standards and nearly 50% of monitoring sites are eutrophic or susceptible to become eutrophic. EEA notes that climate change will accentuate nutrient losses from agriculture: “Heavy rain events can also cause drastic erosion of phosphorus-rich agricultural soils and loss of manure from animal husbandry, resulting in additional phosphorus inputs into surface waters”. The importance of the Farm-to-Fork and Biodiversity Strategy targets to reduce nutrient losses and pesticide use by 50% by 2030 in addressing water quality failures.

EEA indicates that “Recycling nutrients from sewage sludge and manure, such as phosphorus as a non‑renewable resource, increases food security while simultaneously reducing nutrient enrichment of natural water bodies and risks of eutrophication” noting that “sewage sludge can be used beneficially for its nutrients and organic matter content. Similarly, manure from livestock rearing can be recovered. Common uses include land application as a soil conditioner or fertiliser and, in some cases, for energy recovery through biogas production or incineration”.

“Europe's state of water 2024. The need for improved water resilience”, European Environment Agency, EEA Report 07/2024 https://dx.doi.org/10.2800/02236

European Commission Report on Water Framework Directive Implementation

Fewer than 40% of EU surface waters are in Good Ecological Status and fewer than 30% in Good Chemical Status, with nearly no improvement over the last six years. Member States are asked to reduce agricultural nutrient pollution. The Commission report is based on detailed analysis of Member States’ River Basin Management Plan (RBMP) reports and covers c. 90% of EU surface and ground water bodies (97 000 surface water bodies, 15 000 groundwater bodies). The Commission notes that apparent the lack of improvement may be partly because of better monitoring, and because Directive applies the “one out all out approach” (failure for one parameter means classification as overall Quality failure), but that it also results from inadequate measures taken to reduce pollution and inadequate progress in their implementation. Ecological quality status failure (waterbodies not in Good Ecological Status or Good Ecological Potential) is particularly due to eutrophication, confirming findings from the Nitrates Directive reporting (2021) which indicated 30 – 40 % of freshwater surface waters and over 80% of marine waters were eutrophic. For chemical quality status, pollution by mercury, polycyclic aromatic hydrocarbons (PAHs) and brominated flame retardants (PBDEs) are particularly cited, as well as heavy metals, biocides and pesticides and other persistent organic pollutants (e.g. hexachlorobenzene).

Pressures on surface water bodies identified by member states include atmospheric deposition of pollutants (89% of waterbodies), morphological changes (drainage, irrigation, dams, etc, 57%), agricultural pollution (32%) and urban wastewater treatment or non-connection (14%, 9%).

Considering nutrients, it is indicated that nitrates from agriculture (fertilisation, manures, unsustainable land management practices) are the biggest pollutant of groundwater and a problem in surface waters, whereas for phosphorus the biggest source to marine waters remains urban wastewater.

The report reminds that CAP 2023-2027 measures should reduce agricultural pollution, but for the period covered by this report, CAP funding has been insufficient and delayed. It is estimated that CAP 2022-2027 Eco-Schemes and AECCs (Environmental, climate-related and other management commitments) supporting improved nutrient management are planned to cover over 15% of EU agricultural area.

The report notes that “No Member State is using thresholds for nutrient concentrations to assess the good ecological status of surface waters, and only some are determining the required load reduction upstream in the relevant river basin”.

The Commission concludes that groundwaters are largely in good status, but that “surface waters are in a highly critical situation” and that compliance with the Water Framework Directive’s quality status objectives will not be achieved by the 2027 deadline. Key actions needed are identified as increasing funding for implementation of River Basin Management Plan ‘Programme of Measures’ and integration of water into other legislation.

Over 40 action recommendations are given including: “stepping up action to reduce nutrient pollution, including by setting and achieving maximum nutrient loads in all river basin districts, in line not only with the WFD (Water Framework Directive) but also the MSFD (Marine Strategy Framework Directive) and Nitrates Directive”.

A Commission Report on the Marine Strategy Framework Directive (MSFD), issued in parallel to the report on the Water Framework Directive, also underlines that nutrient pollution and eutrophication remain major challenges, especially in the Baltic, North East Atlantic and Mediterranean. It is noted that nutrient pressures will change with climate change. One of 24 recommendation actions is “stepping up action to reduce nutrient pollution to achieve the objectives of the MSFD, WFD and the Nitrates Directive”.

“Protect waters and better manage flood risks”, European Commission press release IP/25/342, 4th February 2025 https://ec.europa.eu/commission/presscorner/detail/en/ip_25_342

Report “on the implementation of the Water Framework Directive (2000/60/EC) and the Floods Directive (2007/60/EC)”, European Commission, COM(2025)2, 4th February 2025 https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2025%3A3%3AFIN&qid=1738678027971

Report “on the Commission's assessment of the Member States’ programmes of measures as updated under Article 17 of the Marine Strategy Framework Directive (2008/56/EC)”, European Commission, COM(2025)3, 4th February 2025 https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2025%3A3%3AFIN&qid=1738678027971

Nutrient recovery

UKWIR report: valorisation of potable water treatment sludges

UK Water Industry Research report analyses current routes and possible improvements for valorisation of iron and aluminium sludges from drinking water treatment (these sludges are completely different from and are not related to sewage sludge). At least 115 000 t/yDM of such sludges are generated in the UK. They contain 2 – 8% dry solids, up to 41% iron or 21% aluminium and significant levels of organics (13 – 26% total carbon). Currently most such iron sludges are discharged to sewers (the iron content contributes to sewage works phosphorus removal and improving settling, so partly substituting virgin coagulant consumption) and the majority of aluminium sludges are spread to land (soil improver, land reclamation). Discharge to sewers can also have negative impacts on sewage treatment (increased sludge production, deterioration of biological treatment, acidity for aluminium sludges). A significant potential valorisation route for iron sludges is addition to anaerobic digesters, with methane generation from organics in the sludge and iron acting to improve anaerobic digester operation and suppress H2S. However, “waste” status of the iron sludge is an obstacle to this valorisation route. Other valorisation routes identified include incorporation into brickmaking, ceramics or construction materials, often after removal of organics (e.g. calcination). Processes to chemically separate iron from phosphorus in such sludges are discussed, in particular sulphuric acid digestion followed by purification (membranes, ion exchange) but these are at the lab scale and to date not economically viable.

“Circular Economy – water treatment sludges”, UKWIR (UK Water Industry Research, the UK water industry’s joint research organisation), 67 pages, 2024, Report Ref. No. 24/SL/09/02 https://ukwir.org/water-industry-research-reports

UN FAO report on nitrogen in agri-food systems

Report on nitrogen in the global food system underlines the importance of dietary choices, spatial misbalances of livestock production and the need to recycle agri-food wastes to livestock feed. FAO (United Nations Food and Agriculture Organisation) explains that nitrogen loss (e.g. nitrates to water, ammonia to air) impact the environment, climate and health. Improving nitrogen management is considered essential to achieving UN Sustainable Development Goals, in particular those relating to water, climate, health and hunger, including increasing food production in lower-middle income countries. FAO estimates that global Nutrient Use Efficiency (NUE) in crop systems is just over 60% (N in output crops / N inputs) and in livestock is 4 – 45% (N in animal – eggs – dairy / N in feed). Overall, N in human food produced is around 30% of global mineral fertiliser inputs and around 15% of total inputs (including biological N fixation and atmospheric deposition). Illustrated data on N international trade is provided and the main cause of N losses in livestock production is identified as feed crop production (with associated mineral fertiliser use and land change). The report notes the potential for reducing protein content of livestock diets (especially cattle), increasing recycling of agri-food wastes to feed (especially pigs) and of improving manure management (e.g. reducing ammonia losses in storage, more efficient application to crops). Priorities for circularity are identified as: reduce food waste, use FLW (food loss and waste) in animal feed (whilst ensuring food chain safety), use arable land to produce human food crops not animal feed and use livestock to convert non-food biomass (e.g. grass) to human food. Promising routes for progress noted include low-emission production of mineral N fertilisers, processing manure, agri-food wastes and industrial wastes to bio-based fertilisers. The need for quality control and appropriate application rates and methods are underlined for organic fertilisers.

“Sustainable nitrogen management in agrifood systems”, FAO (Food and Agriculture Organisation of the United Nations), 130 pages, 2025 https://doi.org/10.4060/cd3388en

See also “Guidelines on the role of livestock in circular bioeconomy systems”, FAO LEAP (Livestock Environmental Assessment and Performance in ESPP eNews n°90 and “Nutrient flow and associated environmental impacts in livestock supply chains. Guidelines for assessment”, FAO in ESPP eNews n°37.

Phosphorus, food and health

Mouse maternal high phosphorus diet impacts offspring mineral metabolism and growth

High phosphorus diet either before or during pregnancy of female mice resulted in offspring with lower gut P uptake, modified levels of blood hormone levels related to mineral metabolism and lower body weight. The female mice were fed either normal (control = 0.8% P) or high-P (1.5% P) diet either for 21 days before pregnancy, or during pregnancy, then normal-P diet during breast feeding of offspring (3 weeks). After weaning, offspring were fed a normal-P diet 3-10 weeks. The high-maternal-P offspring showed no difference in blood plasma P concentrations compared to normal-maternal-P offspring, but showed lower urine P excretion corresponding to reduced gut P-transporter mRNA expression. They also showed modified blood levels of parathyroid hormone, fibroblast growth factor 23 (FGF23) and vitamin D, which are all three related to hormonal mineral metabolism control. Body weight of the high-maternal-P offspring was significantly lower at 3, 6 and 10 weeks of age. The authors note that these animal study results may not transpose to humans and that in this trial only male offspring were studied.

“Maternal excess dietary phosphate intake in the periconceptional period is a potential risk for mineral disorders in offspring mice”, M. Hayashi-Suzuki et al., Scientific Reports, 2025, 15:8844 DOI.

Mouse high P diet leads to heart disease risks

Diets on high phosphorus (2%) showed heart modifications, including atrial fibrosis and oxidative stress, compared to mice on a normal phosphorus diet (0.6%), for both kidney-impaired and non-impaired mice. 8 week old male mice were fed the different diets for 10 weeks, followed by 4 weeks normal-P diet. Half the mice in each group were operated to remove 5/6 of kidney function (partly nephrectomised). The authors conclude that the high P diet increased atrial fibrillation risk. Biological signalling mechanisms are discussed (STAT3, NFKB, Nox4) and collagen expression. The authors note that mouse serum phosphorus is considerably higher than in humans and that previous studies have shown that high P diets in mice lead to increased serum P concentrations, even with non-deteriorated kidney function, whereas this is uncommon in humans. Therefore, high diet P in healthy humans may not lead to similar atrial risks, whereas it is likely to do so for humans with poor kidney function.

“High-phosphate diet causes atrial remodeling and increases atrial fibrillation vulnerability via STAT3/NF-κB signaling and oxidative stress”, Y-J. Hsu et al., Acta Physiologica. 2023;00:e13964 DOI.

Sustainable development of the food & beverage industry

ESPP participated in the 13th Sustainable Development in the Food & Beverage Industry Summit (February, Brussels), presenting on nutrient circularity in the agri-food sector, together with Pär Larshans (Ragn-Sells). The event brought together around 60 participants, including representatives from Ferrero, Danone, Heineken, Unilever, Arla Foods, Fyffes, and OSI Group, to discuss sustainability challenges and strategies across the food value chain. Discussions focused on corporate environmental stewardship, sustainable sourcing, and the role of data in driving innovation. Companies exchanged views on ways to measure and reduce the environmental footprint of food production, with attention to eco-design, procurement, decarbonisation, and regenerative agriculture. A key takeaway was the need for reliable data and assessment tools to advance circularity and sustainability goals.

13th Annual Sustainable Development in the Food & Beverage Industry Summit, 4-5 February 2025, Brussels, website

ESPP slides available on slideshare.

Commiserations

Waltraud Hermann, wife of ESPP Secretary and previously President, Ludwig Hermann, sadly died on 13th March. Many ESPP contacts met Waltraud Hermann and appreciated her energy and enthusiasm. We will regret her and all our thoughts are with Ludwig and his family. If you wish to make a gesture, Waltraud wished for donations to the association SOS Mitmensch, Austria, https://www.sosmitmensch.at/site/ueberuns IBAN AT12 2011 1310 0220 4383

Stay informed

SCOPE Newsletter: www.phosphorusplatform.eu/SCOPEnewsletter eNews newsletter: www.phosphorusplatform.eu/eNewshome

If you do not already receive ESPP’s SCOPE Newsletter and eNews (same emailing list), subscribe at www.phosphorusplatform.eu/subscribe

LinkedIn: https://www.linkedin.com/company/phosphorusplatform

Slideshare presentations: https://www.slideshare.net/phosphorusplatform - Twitter: @phosphorusESPP

YouTube https://www.youtube.com/user/phosphorusplatform

ESPP members

Newsletter about nutrient stewardship - European Sustainable Phosphorus Platform (ESPP)

Please subscribe www.phosphorusplatform.eu/Subscribe

Link to www.phosphorusplatform.eu/eNews094

Download as PDF

Events

Phosphorus use and recycling in intensive livestock: 5-7 March 2025

13th March 2025: EU sewage phosphorus “reuse & recycling” targets

10-12 June 2025, Bergen, Norway, nutrients in aquaculture and fisheries

15-17 October 2025, Wageningen, NL. RAMIRAN: the manure management event

EU consultations

Evaluation of EFSA

Evaluation of public procurement directives

EU fertiliser imports

Limited EU proposal for tariffs on Russian fertilisers

Circular Economy policy

BusinessEurope priorities for Circular Economy

EESC calls for policies to move “from waste plants to resource plants”

ESPP new members

STEPS Science and Technologies for Phosphorus Sustainability Center

REALM Reusing Effluents from Agriculture to unLock the potential of Microalgae

Regulatory questions on biomass from waste

ESPP workshop on legal status of algae & biomass grown in wastes

Legal Opinion: algae from waste, manure, minerals recycling to animal feed

Nutrient recovery

Culterra obtains EU fertilising products CE-mark

EasyMining demonstrates iron recovery with Ash2Phos P-recovery process

Canada Biogas Association points to important role of digestate in nutrient recycling

NEWTRIENT ‘Solutions Catalog’ evaluates over 500 dairy manure technologies

ReLEAF questionnaire for farmers on bio-based fertilisers

Flashphos pilot P4 recovery pilot starts testing

Research

Eutrophication – climate change link

Smart phone fluorescence quantification of inorganic phosphates

Stay informed

ESPP members

Events

Phosphorus use and recycling in intensive livestock: 5-7 March 2025

This event will focus on making livestock production, animal feed, and manure and digestate management more circular. The workshop will help create a UNEP report on sustainable nutrient use in livestock farming.

How can we balance efficient nutrient management in intensive livestock farming with social benefits (such as lower prices and regional agri-food specialisation) while tackling nutrient imbalances in certain areas?

- Location: Saint Malo, Brittany (with some sessions online)

- Topics Covered: • Sustainable livestock nutrient management • How nutrients move in livestock production, • The impact of different diets on nutrient use, • Animal feed, farming methods, and nutrient footprints, • Life cycle analysis (LCA) of livestock production, • Recycling and reusing manure nutrients

- Participants: Experts from UNEP (United Nations), the European Commission (DG AGRI, DG RTD), livestock farmers, meat producers, the agri-food industry, environmental organisations, and researchers.

- Organisers: UNEP uPcycle, Roullier (fertilisers, animal nutrition, food industry), Cooperl (Brittany pig farmers and pork industry solutions), ESPP, BETA Technological Center, UK Centre for Ecology & Hydrology (CEH).

In-person participants have the opportunity of site visits:

- Roullier’s Global Research Centre (fertilisers and agriculture)

- Minerallium, a unique experience exploring minerals from Earth’s origins to plants, animals and humans

- Cooperl’s waste to resource vision and processes, with the Bulle Environment immersive showroom

- Couiclang pig farm, state-of-the-art pork production sustainability

On-site participation limited to 60 persons to enable active discussion, white paper drafting, site visits. Wed. 5 – Fri. 7 March 2024, Saint Malo, France (Brittany coast, 1 hour from Rennes high-speed train station and airport) and partly online. Online access will include plenary presentations. To participate in discussions and white paper, we recommend in-person attendance. To request to participate in Saint Malo, pre-register now: https://phosphorusplatform.eu/LivestockBrittany

13th March 2025: EU sewage phosphorus “reuse & recycling” targets