Newsletter about nutrient stewardship - European Sustainable Phosphorus Platform (ESPP)

Please subscribe www.phosphorusplatform.eu/Subscribe

Link to www.phosphorusplatform.eu/eNews062

Download as PDF

ESPP 2021 summary

Phosphorus events

Legacy Soil Phosphorus webinar: Wednesday 2nd February, 14h - 17h CET

Recovered phosphates for animal feed

ESPC4 programme published: 20-22 June 2022, Vienna Austria & online

PERM5 - the 5th Phosphorus in Europe Research Meeting

Phosphates 2022

Supply challenges

EU regulatory

BAT BREF update process launched for Inorganic Chemicals

Input to EU Fertilising Products Regulation: by-products, recovered minerals

ESPP new member

REFLOW

Nutrient recycling

Micronutrients recovered from alkaline batteries as Organic Certified fertiliser

EasyMining moves forward nutrient recovery

Webinars

IFA – FAO: Nutrient recovery and sustainable plant nutrition

Implementation of the Baltic Sea Regional Nutrient Recycling Strategy

Research

Possible P4 synthesis by electrolysis

Climate variability likely to increase soil phosphorus losses

Scientific testing of options for P-leaching from ashes

Overview of sewage sludge regulations in Europe

Stay informed

ESPP members

ESPP 2021 summary

ESPP wishes our readers all the best for 2022, whatever it may bring. We summarise below our main actions in 2021 and perspectives for 2022. More information is in past issues of eNews and our SCOPE Newsletter on our website.

In 2021, ESPP continued active input to the EU Fertilising Products Regulation FPR 2019/1009, which will enter into implementation in July 2022. After some delays, the criteria were published for recycled struvite and precipitated phosphates (2021/2086), use of ashes in fertiliser production (2021/2087), and biochars / pyrolysis materials (2021/2088). Proposals are now underway to also cover nitrogen salts recovered by ammonia stripping from digestates, phosphogypsum and certain by-products (see below). Work is engaged to cover post-processing of digestates and composts. The FAQ continues to be extended (Frequently Asked Questions document, providing implementation and interpretation guidance).

ESPP is also working on authorisation of use of recovered nutrients in Organic Farming (see FIBL in ESPP eNews n°60).

2021 also saw significant developments towards implementation of nutrient recovery, with a number of companies progressing pilot and full-scale installations. These are summarised in the ESPP-DPP-NNP Catalogue of Nutrient Recovery Technologies (update underway, input welcome).

2021 saw publication by JRC of the MSA (System Analysis) for P4 (white phosphorus and derivates), based on the workshop on P4 co-organised by the European Commission and ESPP in 2020 (SCOPE Newsletter n°136). Both phosphate rock (i.e. phosphorus in fertilisers and food) and the specific material P4 (essential for a range of chemicals) are EU Critical Raw Materials.

In the context of the EU Algae Initiative, ESPP organised a webinar to explore regulatory questions concerning algae grown using waste inputs (e.g. grown in wastewater, or using off-gas CO2 …), and with EABA and Eureau, has formally put resulting questions to the European Commission.

ESPP also organised a working webinar on regulatory obstacles to recycling manure to fertilisers, and will pursue this further with the European Commission and EFSA (European Food Safety Agency) in 2022.

ESPP organised the 4th PERM5 Phosphorus in Europe Research Meeting, with over 370 participants online (see SCOPE Newsletter n°141).

In 2022, the 4th European Sustainable Phosphorus Conference: ESPC4 Vienna 20-21 June 2022 will be the biggest phosphorus stakeholder meeting globally for 4 years (since ESPC3 Helsinki, with 300 participants from 30 countries, see SCOPE Newsletter n°127). Programme with many confirmed speakers to date is online here and registration is open. and will be followed by the 5th Phosphorus in Europe Research Meeting, PERM5 Vienna, 22 June 2022. Both events will be ‘hybrid’, with networking tools enabling dialogue between online participants and those meeting in Vienna throughout the duration of the conferences. We look forward to seeing you there! https://phosphorusplatform.eu/espc4

ESPP will continue our action on sustainable nutrient use on farm, with a webinar on relationships between draw-down of “Legacy P”, crop yield and P losses, on webinar 2nd February 2022, 13h – 17h CET, www.phosphorusplatform.eu/LegacyP

2022 will also see implementation of the important decisions taken by ESPP’s General Assembly 2021 (webinar and email vote): recruitment of a second staff in Brussels and widening of ESPP’s action (currently all aspects of phosphorus sustainability) to cover recovery and recycling of nitrogen and other elements.

Phosphorus events

Legacy Soil Phosphorus webinar: Wednesday 2nd February, 14h - 17h CET

This ESPP webinar, co-organised with BOKU, will look at relationships between draw-down of “Legacy P” in soil, crop yield and P losses. Full programme is online here. The webinar will address: what do we mean by “Legacy P”, impacts of drawing down Legacy P on crop yields and on soil phosphorus (long-term field trials) and Legacy P or draw-down impact losses to surface waters. Confirmed speakers are from The Netherlands, Poland, Sweden, Switzerland, UK, Russia, Arkansas, Delaware, Illinois, Maryland, Canada, Brazil and New Zealand. Panellists are leading agronomists and environmental experts from research centres and from the fertilisers industry.

This ESPP webinar follows on from the SPA (US) webinar “A Legacy of Phosphorus”, 30th September 2021, and from the Frontiers in Earth Science special on ‘Legacy Phosphorus’ summarised in ESPP eNews n°56.

Programme and registration (free): www.phosphorusplatform.eu/LegacyP

Recovered phosphates for animal feed

Webinar 3rd February 13h - 14h30 CET. Results of trials of recovered phosphates as animal feed, quality and sustainability, regulatory barriers. With EasyMining, Gelsenwasser, SLU, Lanmännen, ESPP.

LINK: https://www.easymining.se/projects/feed-phosphate/webinar3febr/

ESPC4 programme published:

ESPC4 programme published:

20-22 June 2022, Vienna Austria & online

https://phosphorusplatform.eu/espc4

The detailed programme of the

4th European Sustainable Phosphorus Conference (ESPC4)

is now published.

Confirmed speakers include Virginijus Sinkevičius European Commissioner for Environment; Sibylla Hardmeier, Swiss Federal Office for the Environment (BAFU); Andrea Roskosch, German Federal Environment Agency (UBA); Franz Josef Radermacher, Research Institute for Applied Knowledge Processing (FAWn), Germany; Mahesh Pradhan, United Nations Environment; Wenfeng Liu, China Agricultural University …

ESPC4 (20-21 June 2022, Vienna and hybrid) will be the first major phosphorus stakeholder meeting globally for 4 years (since ESPC3 Helsinki, with 300 participants from 30 countries, see SCOPE Newsletter n°127).

The published programme includes pre-selected speakers for the six ESPC4 parallel sessions:

- Nutrient recovery technologies operational showcase

- Nutrient recovery technologies in development

- Phosphorus recovery from ashes

- Biochars and hydrothermal carbonisation

- Regional nutrient policies and actions

- New and bio-based fertilisers

ESPC4 will include a Nutrient Recovery Technology Fair, with stands, presentations and possibility to meet technology suppliers presented in the ESPP-DPP-NNP Catalogue of Nutrient Recovery Technologies, currently being updated (see below).

https://phosphorusplatform.eu/espc4

PERM5 - the 5th Phosphorus in Europe Research Meeting:

22 June 2022, Vienna, Austria

ESPC4, Monday 20th and Tuesday 21st June 2022, will be followed by PERM5, the 5th Phosphorus in Europe Research Meeting, Wednesday 22nd June 2022, making the link between R&D, industry and policy (summary of PERM4, June 2021, 370 participants, in SCOPE Newsletter n°141).

Sessions proposed include: nutrient recovery in the dairy industry, iron and phosphorus interactions, new fertilisers and biostimulants to improve crop nutrient uptake, Farm-to-Fork Zero Pollution: reducing P losses from agriculture, nature based solutions, decentralised sanitation / separative urine systems, nutrient flow studies …

A call for abstracts for PERM is open, deadline for submission 27th February.

ESPC4 - PERM5 will be both in Vienna and online.

Updated outline programmes of ESPC4 and PERM5 https://phosphorusplatform.eu/espc4

Phosphates 2022

7 – 9 March 2022, Tampa, Florida. Programme now online. This is “the” phosphate industry professional conference, with over 400 participants. Phosphates 2022 will be in-person (with an online option), and a major chance to re-connect with the phosphate industry, from mining through rock and acid processing, to fertilisers, feed phosphates and technical phosphates. The two-day conference will have a dual agenda: commercial - market – regulatory, and technical and industry operational. 10% discount for ESPP members: request the code from ESPP.

7 – 9 March 2022, Tampa, Florida. Programme now online. This is “the” phosphate industry professional conference, with over 400 participants. Phosphates 2022 will be in-person (with an online option), and a major chance to re-connect with the phosphate industry, from mining through rock and acid processing, to fertilisers, feed phosphates and technical phosphates. The two-day conference will have a dual agenda: commercial - market – regulatory, and technical and industry operational. 10% discount for ESPP members: request the code from ESPP.

CRU Phosphates 2022: https://events.crugroup.com/phosphates/home

Supply challenges

Nitrogen fertilisers and P4 (white phosphorus) currently face interlinked global supply challenges, with links to global food price increases.

Nitrogen fertilisers and P4 (white phosphorus) currently face interlinked global supply challenges, with links to global food price increases.

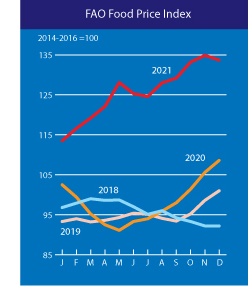

The FAO’s Food Price Index hit a ten-year high in 2021 and was 23% higher in December 2021 than one year earlier (after falling 1% between November and December 2021.

BBC coverage suggested that causes include climate change, leading to bad harvests, shortages of migrant workers, shipping problems due to Covid and deregulation of futures markets. Rabobank expects food prices to remain high in 2022, because of increasing prices of fertilisers and energy, shipping and labour shortages, continuing adverse weather (climate change, La Niña) and a strong US dollar.

Nitrogen fertiliser prices are closely linked to natural gas prices, and natural gas prices have increased considerably recently, as a result of various factors including geopolitics, climate, supply and demand policies (see e.g. this US analysis). The N fertiliser price is being exacerbated by export bans or limitations from China and Russia.

A study by Texas A&M University shows, for July 2021, N fertilisers at their highest price ever, and both P and K at their highest price since the 2008 price spike (but P still nearly 40% lower than this peak).

Despite high prices, fertiliser demand is expected to continue to increase in 2022 (according to CRU, organisers of the “Phosphates” industry conferences), with an expected rise of +2.9% from 2021 to 2022, following from the +1.2% rise 2020 to 2021.

Trade of phosphorus fertilisers is being impacted by the US decision to impose tariffs of 9% to 47% on some P imports, and then China’s decision to freeze phosphate exports from September 2021 to (at least) June 2022.

The specific market for P4 (white phosphorus) and its derivates is also being impacted by the energy squeeze and by political factors. Although P4 represents only 2-3% of world phosphate rock consumption, it is irreplaceable for the production of many specialist phosphorus chemicals needed by a very wide range of high-value societal end-uses, including electronics, batteries, fire safety, industrial water treatment, technical plastics, pharmaceuticals, lubricants, metal treatment, … (see ESPP’s SCOPE Newsletter n°136, produced jointly with the European Commission JRC). P4 is therefore itself specifically identified as an EU Critical Raw Material (in addition to “Phosphate Rock”), see COM(2020)474. P4 is traded as such, but also importantly as “derivates” (that is intermediate chemicals such as PMIDA, POCl3, PCl5, see SCOPE referred above).

The EU has no production of P4 and so is totally dependent on imports of either P4 or of P4-derivates for essential user industries. Europe imports P4/derivates essentially from China, Kazakhstan and Vietnam (not in order of importance). In 2021, China considerably reduced its exports of P4/derivates, mainly because of nearly total stoppage of China’s P4 production capacity in order to energy consumption in particular in Yunnan province (a key phosphate region). Production has now partly resumed. Kazakhstan’s P4 / derivates production or export have also been impacted by current political unrest in the country and specifically in the Zyambyl Oblast region where P4 production is located (see here). These specific pressures on P4/derivates supply are additional to considerable price and supply pressures similar to those on fertilisers indicated above: rising electricity prices and demand, and shipping costs.

ESPP suggests that this context should provide increased impetus and urgency to develop phosphorus and nitrogen recovery and recycling in Europe. Nitrogen recovery from digestates offers synergy with development of bio-methane production, which can reduce EU dependency on imported natural gas. Industrial development and implementation of P4 production from secondary materials (sewage sludge incineration ash, meat and bone meal ash) could largely resolve Europe’s current import dependency for P4/derivatives.

No market-ready P4 production technology from waste is available at the moment. However, several promising developments are in a piloting stage. ESPP member Italmatch are involved in the EU-funded FlashPhos project to test P4 recovery from wastes at a pilot scale (15 million € budget). Other technologies are also proposed and are being tested on small scale.

EU regulatory

BAT BREF update process launched for Inorganic Chemicals

The European Commission (JRC) has started the update process for the BAT (Best Available Techniques) reference document for “Large Volume Inorganic Chemicals” (LVIC), which will cover all chemicals currently covered by the two BATs: LVIC Ammonia, Acids and Fertilisers (LVIC-AAF) and LVIC Solids and Others (LVIC-S). The first phase of consultation aims to define the scope of the BAT update, in particular to identify the most polluting sectors, key environmental issues (e.g. in terms of emissions to air and water, use of raw material, water and energy, generation of waste, circular economy, decarbonisation aspects) and new/emerging techniques or improvements in techniques which should be considered, compared to the two existing BAT BREF documents. The aim is to streamline the BAT BREF document by focussing on the BAT conclusions (and associated techniques). The BAT conclusions are legally constraining, and are mandatory applicable to all plants and production sites in the relevant chemical and fertiliser industries above the specified application thresholds. ESPP has not been a candidate for the Technical Working Group for this BAT BREF process (insufficient resources, scope much wider than ESPP’s competence) but will follow the process as a member of the IED Forum (Industrial Emissions Directive).

Existing BAT BREFs for LVIC Ammonia, Acids and Fertilisers (LVIC-AAF) and LVIC Solids and Others (LVIC-S).

European Commission (JRC) contact for further information on the LVIC BAT update process:

Input to EU Fertilising Products Regulation: by-products, recovered minerals

ESPP submitted input to the EU public consultations on criteria for use under the EU Fertilising Products Regulation (FPR) of by-products and of recovered minerals.

These criteria will authorise the use in FPR EU-label fertilisers of nitrogen salts from offgas cleaning and ammonia stripping, under specified conditions. ESPP strongly welcomes this but considers that where nitrogen salts are recovered from manure storage, manure processing (e.g. digestate) or animal stables, pathogen data is needed to prove sanitary safety and an Animal By-Product End Point should be defined.

ESPP also welcomes that the inclusion of phosphogypsum and of e.g. struvite recovered from treatment of discharge from phosphogypsum waste stacks.

We regret however that CMC11 and CMC15 as proposed are limited to high-purity inorganic salts and do not cover organic by-products

ESPP also made detailed input concerning wording, such as whether the wording “substance and mixture” includes plant materials, whether processes using wastes as inputs are included and the meaning of the word “recovered”.

ESPP’s input to the public consultation, as well as various preparatory documents (including the JRC reports) are available at www.phosphorusplatform.eu/regulatory.

ESPP new member

REFLOW

REFLOW is an interdisciplinary cross-sectoral European Training Network addressing the recovery of phosphorous from dairy processing waste water and its recycling into fertiliser products. REFLOW brings together scientists, key stakeholders and early-stage researchers in dairy processing, phosphorous recycling and fertiliser production. The network will address both technical and socio-economic challenges associated with the P-recovery and recycling in the dairy sector, so enabling sustainable expansion of the dairy industry in Europe.

REFLOW is an interdisciplinary cross-sectoral European Training Network addressing the recovery of phosphorous from dairy processing waste water and its recycling into fertiliser products. REFLOW brings together scientists, key stakeholders and early-stage researchers in dairy processing, phosphorous recycling and fertiliser production. The network will address both technical and socio-economic challenges associated with the P-recovery and recycling in the dairy sector, so enabling sustainable expansion of the dairy industry in Europe.

In coherence with the Circular Economy Package, REFLOW research aims to (i) mitigate the environmental impact of dairy processing waste on soil and water, (ii) provide safe environmentally sustainable, cost-effective closed loop solutions for crop nutrient management and (iii) meet the demand for skilled professionals to support the technical, regulatory and commercial development of the market for recycled phosphorous fertiliser products.

REFLOW will achieve these goals by creating an innovative and entrepreneurial training environment. Thirteen young researchers will be recruited in a network of 24 organisations who bring complementary expertise and experience of delivering technical solutions, socio-economic modelling, environmental analysis, policy frameworks, training and commercial entrepreneurship. The young researchers will develop interdisciplinary and cross-sectoral skills for careers as independent industrial or academic researchers, entrepreneurs, regulators or agri-environmental specialists. REFLOW’s network-wide training activities include industrial secondments and commercially driven research projects.

Reflow European Training Network https://etn-reflow.eu/

Nutrient recycling

Micronutrients recovered from alkaline batteries as Organic Certified fertiliser

TraceGrow, Finland, are recovering manganese, zinc and copper from alkaline batteries and reclaimed copper to produce a high-purity foliar or soil micronutrient fertiliser, approved for Organic Farming in the EU. 50% of the world’s soils are deficient in zinc and 10% in manganese. These micronutrients are recovered from end-of-life consumer alkaline batteries by crushing, acid leaching then purification to generate soluble sulphates, plus copper recovered from end-of-life electronics and electrical parts. 15 batteries produce one litre of micronutrient fertiliser (4.1% Zn, 4.4% Mn, 1.9% Cu, 6.1% S, plus c. 1% K, 1% Na). TraceGrow has 35 million l/y production capacity, under expansion to 5 Ml/y. The fertiliser shows field trial results from twelve countries on barley, wheat, maize, potato, grass, citrus fruit. Manganese can be particularly effective in improving winter crop resistance to cold, and copper is important for grain yields in oats and barley. The product illustrates the need to continue to extend the CMC annexes of the EU Fertilising Products Regulation 2019/1009, in that it is not covered by current CMCs nor by the proposed new CMC15 “Recovered High Purity Materials” (published for public consultation to 14th January 2022): this proposal includes high purity sulphates, but only from a “production process” (EU Commission JRC’s 3rd preparatory report specifies line 2823 excludes “Materials obtained from the recycling facilities for waste materials”).

TraceGow “ZM-Grow”: https://www.tracegrow.com/zm-grow

EasyMining moves forward nutrient recovery

ESPP member, EasyMining (part of the Ragn-Sells Group) has announced a first full-scale Ash2Phos plant to recover phosphorus from sewage sludge incineration ash (SSIA) and has started testing of a pilot installation to recover nitrogen from wastewaters.

The Ash2Phos plant is a joint venture, signed with Gelsenwasser AG, one of Germany’s largest utility companies operating mainly in the Ruhr, Muensterland, lower Rhein and Eastern Westphalia regions. Construction of a 30 000 t-ash/year plant will start in 2022 in Chemieparks Schkopau, near Leipzig. The Ash2Phos process leaches phosphorus out of ash using hydrochloric acid, then separates iron, aluminium and heavy metals by a series of dissolution and precipitation steps, resulting in a clean calcium phosphate product of animal food quality. A second 30 000 t-ash/y plant is under permitting at Helsingborg, Sweden, with Kemira. For further details see the ESPP-NNP-DPP Nutrient Recycling Technology Catalogue.

A webinar on 3rd February, 13h00 - 14h30 CET will discuss results of digestibility tests for calcium phosphates recovered from sewage sludge incineration ash, quality constraints and regulatory obstacles.

EasyMining have also inaugurated the first pilot for a nitrogen recovery process, at Högbytorp, near Stockholm, in the EU LIFE funded project “Re-Fertilize”. Ammonia in wastewater is adsorbed to a specific mineral, then released and recovered, to produce clean ammonium sulphate. This can replace ammonia synthesised using natural gas, for fertiliser production. The adsorption chemical is regenerated and reused. The aim is also to replace current nitrogen removal processes in wastewater treatment (nitrification of ammonia to nitrate, then denitrification), which consumer electricity for aeration (nitrification) and carbon sources (e.g. methanol) for denitrification, and which release greenhouse nitrogen gases to the atmosphere. The pilot, designed and constructed by EasyMining with COWI and ENERCO, can treat c. 100 m3 of inflow per day, under continuous operation. It is now treating landfill leachate at Ragn-Sells Högbytorp site, Sweden, and will then be moved to BIOFOS´s Lynetten municipal wastewater treatment works in Denmark. The resulting ammonium sulphate fertiliser will be trialled by the Lantmännen, one of Northern Europe’s largest agricultural cooperatives.

EasyMining have also inaugurated the first pilot for a nitrogen recovery process, at Högbytorp, near Stockholm, in the EU LIFE funded project “Re-Fertilize”. Ammonia in wastewater is adsorbed to a specific mineral, then released and recovered, to produce clean ammonium sulphate. This can replace ammonia synthesised using natural gas, for fertiliser production. The adsorption chemical is regenerated and reused. The aim is also to replace current nitrogen removal processes in wastewater treatment (nitrification of ammonia to nitrate, then denitrification), which consumer electricity for aeration (nitrification) and carbon sources (e.g. methanol) for denitrification, and which release greenhouse nitrogen gases to the atmosphere. The pilot, designed and constructed by EasyMining with COWI and ENERCO, can treat c. 100 m3 of inflow per day, under continuous operation. It is now treating landfill leachate at Ragn-Sells Högbytorp site, Sweden, and will then be moved to BIOFOS´s Lynetten municipal wastewater treatment works in Denmark. The resulting ammonium sulphate fertiliser will be trialled by the Lantmännen, one of Northern Europe’s largest agricultural cooperatives.

“Gelsenwasser and EasyMining announce joint venture in Germany”, EasyMining 14th December 2021

“Unique pilot plant for nitrogen removal and recovery opens”, EasyMining, 9th December 2021

EU LIFE Re-Fertilize project

Webinar on recovered feed phosphates, 3rd February 13h00 – 14h30 CET LINK.

Webinars

IFA – FAO: Nutrient recovery and sustainable plant nutrition

The IFA - FAO webinar of 15th December 2021, 300 participants online, saw nutrient circularity as important for sustainability and showed a range of nutrient recycling technologies. IFA and FAO have also signed an agreement to promote sustainable fertiliser use.

Jiangyuan Xia, FAO Director of Plant Production and Protection, indicated that FAO believes that innovation can enable more sustainable plant nutrition management. This is pressing with the current energy crisis driving up fertiliser prices. FAO supports this with the International Code of Conduct for the Sustainable Use and Management of Fertilizers (2019, see ESPP eNews n°45).

Achim Dobermann, IFA Chief Scientist (International Fertilizer Association), indicated that only around 20% of nitrogen input into agriculture reaches consumed food and underlined the need to move towards full-chain nutrient efficiency for nitrogen, phosphorus and micronutrients.

Hannah Van Zanten, Wageningen University Research, compared land surface required to produce food for different food systems. Under today’s food system, animal production has a significantly higher environmental impact and land use than vegetable crop production. However, a circular food system producing healthy food can be even more efficient if food wastes are used to feed animals. In such a system, around 1/3 of human protein needs could be produced by livestock, and such a circular system with livestock could have a lower land requirement than for a vegan diet. Recycling of manure and animal by-products are essential. For further information see website and Van Selm et al. Nature Food 2022 DOI.

Hannah Lohman, University of Illinois & Community Integrated Development Initiatives, Uganda, discussed the potential for separative urine collection with nutrient recycling to fertiliser in Kampala, Uganda, either by simple storage of the urine to ensure sanitisation, or nutrient recovery by struvite precipitation and ion-exchange nitrogen recovery. Both routes could potentially be economically viable, depending on nutrient market prices. A challenge could be pharmaceuticals in the urine.

Céline Vaneeckhaute, Laval University Canada, presented the advances and limitations, as well as experimental work on various nutrient recovery technologies including struvite precipitation, HAIX ion exchange (see SCOPE Newsletter n°141), nitrogen recovery by stripping and citric acid absorption, and development of technology integration and optimisation models.

Dan Froehlich, Anuvia Plant Nutrients, presented the company’s SymTRX granulated organo-mineral fertiliser, based on organic secondary materials processed to provide a matrix with +ve and -ve sites onto which mineral nutrients can be fixed. After 5 years development and over 450 field trials, production capacity is today 1.1 million tonnes / year at Plant City, Florida. Organic wastes which can be input include crop wastes, animal wastes, food processing wastes and waste-water organics. Less than 5% of the nutrients of the final product come from the organic wastes, most are added as minerals, depending on the input materials.

Christian Kabbe, EasyMining, outlined the company’s processes today operational to recover purified nutrients from ashes: phosphorus from sewage sludge incineration ash, potassium from municipal solid refuse incineration ash. EasyMining are also now developing a process to recover nitrogen minerals from wastewater or manure.

Thomas Mannheim, Ductor, outlined the company’s integrated approach to nutrient recycling and renewable energy production from manure, aiming to avoid the considerable nitrogen losses (and consequent atmospheric pollution and greenhouse gas) which generally occur in manure storage and field application (can be up to 70%). In the Ductor process, nitrogen rich manures can be used as feedstock for biogas production (e.g. 100% chicken litter), because most of the nitrogen is removed upstream of the anaerobic digestion (biogas) process. The removed nitrogen is recovered as liquid nitrogen fertiliser. The solid fraction of the separated digestate is dried and pelletised as organic NPK fertilizers, and the liquid phase is recirculated to dilute the input material. This results in reduced GHG emissions and enhanced nutrient use by converting untreated manure to bioenergy and to balanced nutrient products which can be stored and transported and are adapted to farmers’ needs.

Achim Dobermann concluded that many technologies are increasingly available for nutrient recycling, and their implementation will improve sustainability of plant nutrition. The fertiliser industry is innovating with new types of products alongside mineral fertilisers and the use of secondary nutrient sources in fertiliser production. This will necessitate decentralisation to enable local recycling, adapted to local structures and agri-food systems, in particular in developing countries.

IFA – FAO webinar, 15th December 2021, “Advancing nutrient recycling and recovery in agriculture” (Sustainable Plant Nutrition series): full recording and IFA webinars page.

Upcoming IFA events HERE:

- 29-31 March 2022, Global Sustainability Conference, online

- 30 May - 1st June 2022, Annual Conference, Vienna, Austria

- 28-30 June 2022, Smart & Green, online

Implementation of the Baltic Sea Regional Nutrient Recycling Strategy

The EU Strategy for the Baltic Sea Region together with the Ministry of the Environment of Finland co-organized a webinar on the implementation of the Baltic Sea Regional Nutrient Recycling Strategy on Monday 22 November 2021.

The purpose of the webinar was to present some topical issues and points of view in nutrient recycling, take stock of the present situation in nutrient recycling and also to look ahead and discuss opportunities and challenges in implementing the Nutrient Recycling Strategy in the Baltic Sea Region.

The webinar gathered c. 120 participants representing national authorities, businesses, research organisations and NGOs from different countries across the Baltic Sea.

The morning session consisted of five presentations from experts across public and private sectors. In her opening words, Tarja Haaranen, Ministry of the Environment, Finland, reminded that although the main goal of the strategy is to protect waters and the Baltic Sea, the actions will also have other beneficial impacts, among them impact on climate change mitigation.

In her introduction to the Baltic Sea Regional Nutrient Recycling Strategy, Lotta Ruokanen, HELCOM, focused on the policy background, vision and objectives of the strategy.

Isidro Campos Rodriguez, European Commission DG Agriculture and Rural Development, gave an overview of nutrient recycling in the European Green Deal’s Farm to Fork programme, the Common Agricultural Policy, and beyond, and presented some links between these and the nutrient recycling strategy.

Ana-Lucia Crişan, European Commission DG GROW, presented the EU fertilising products regulation and discussed the harmonisation rules for fertilising products and gave an overview the quality assurance system works for fertiliser manufacturers.

Anders Finnson, Swedish Water, focused on the experiences in nutrient recycling in the wastewater sector in Sweden. He presented the ambition to transform the current wastewater treatment system into resource recovery plants.

Christian Kabbe, EasyMining (Ragn-Sells Group), focused on the business opportunities and obstacles of nutrient recovery and recycling. Some of the clear drivers, or opportunities that he mentioned were the existing quality requirements to minimize pollution and the need to reduce import dependencies. Some of the obstacles he mentioned were the discrimination of materials by origin and not by quality and the fragmentation of regulation.

In the afternoon session, six experts took part in a panel discussion on the present situation in nutrient recycling and took a look ahead and discussed opportunities and challenges in implementing the HELCOM Nutrient Recycling Strategy focusing on creating business opportunities and improving policy coherence.

The panel included representatives of national authorities, businesses and NGOs from different countries of the Baltic Sea Region: Andrea Roskosch (German Federal Environment Agency), Marja-Liisa Tapio-Biström (Ministry of Agriculture and Forestry of Finland), Zigmas Medingis (Ministry of Agriculture of the Republic of Lithuania), Eetu Virtanen (Soilfood), Marc Buttmann (TerraNova Energy GmbH), and Gunnar Norén (Coalition Clean Baltic).

Article by Anna Hernberg, Ministry of the Environment, Finland – with thanks!

Webinar website –summary and slides: HERE

Research

Possible P4 synthesis by electrolysis

Lab-scale tests suggest feasibility of P4 production by electrolysis of molten metaphosphates (from phosphoric acid), potentially with energy and carbon consumption magnitudes lower than the current “thermal” route (electrothermal reducing furnaces). A 60 cm diameter, 2.8m height laboratory electrolysis reactor, operating at c. 800°C, and 2.4V current, was tested with steady-state electrolysis runs of a few minutes. Challenges are design and construction of an electrolysis cell reactor for operation at this temperature, sealings and recovery of the P4 produced. The principle is electrolysis of molten sodium metaphosphate [NaPO3]n – a commodity inorganic phosphate produced from “wet acid” route phosphoric acid. Sodium metaphosphates is an intrinsic oxide acceptor (because of phosphoryl anhydride linkages) so absorbing electrons to break down to NA3PO4 and O2. The NA3PO4 can then be cycled back to sodium metaphosphate by reaction with phosphoric acid. In the test reactor, the graphite anode was consumed, producing CO2, but unlike in a reducing P4 furnace, this CO2 is isolated from and cannot react with P4, so avoiding resulting energy loss. Additionally, the electrolysis reactor does not require sand (silicon dioxide) as an oxide acceptor, so does not lose heat energy in production of metasilicate slag (c. 30% of energy consumption in a P4 reducing furnace). The melting point of sodium metaphosphates (628°C) is considerably lower than the operating temperature of P4 reducing furnaces (c. 1 500 °C). To avoid CO2 reacting with P4, thermal P4 furnaces currently only partially reduce coke to carbon monoxide, which is burned off, so using only two of the four potential reducing electron equivalents of the coke carbon. The authors conclude that anhydride promoted electroreduction of molten metaphosphates could in the future provide an electron, energy and climate efficient alternative to electrothermal reducing furnaces for P4 production.

“Efficient Electrosynthesis of White Phosphorus from Molten Condensed Phosphate Salts”, J. Melville et al., ChemRxiv. Cambridge 2021, LINK.

Climate variability likely to increase soil phosphorus losses

Laboratory soil tests showed that simulated flooding caused P release in all soil samples, accentuated if the soil was previously dried, suggesting that climatic variations between drought and flooding could increase P losses. 168 soil samples of 150g (dry weight equivalent) were collected over 7 days from two different sites in North Wyke, Devon, UK (stagni-vertic cambisol, dystric cambisol), both under grazed grassland. 31 day laboratory tests were carried out in 500 ml bottles. Flooding was simulated by adding water to maintain 10 cm water depth in the mesocosm. Drying was for 10 days at 40°C. Flooding of soils significantly reduced redox potential, more so and more rapidly in previously dried soils. Similarly, flooding increased soil pH, more so and more rapidly in previously dried soils. Flooding increased dissolved phosphorus (DRP dissolved reactive P, DUP dissolve unreactive P and TDP total dissolved P), again with greater increases of all forms in flooding of previously dried soils. Analysis suggests this is related to reductive dissolution of iron and manganese phosphate minerals in the soils, and also non-reductive dissolution of aluminium phosphate minerals. The soil with higher organic matter and biomass phosphorus released higher concentrations of DUP. The authors conclude that as climate change leads to flooding, and to variations between drought and flooding, P release from soils will increase, especially in soils high in biomass.

“Effects of drying and simulated flooding on soil phosphorus dynamics from two contrasting UK grassland soils”, S. Khan et al., Eur J Soil Sci. 2021;1–12, DOI

Scientific testing of options for P-leaching from ashes

Three papers present detailed and systematic experimental comparisons of phosphorus and of heavy metal leaching from ashes of various biowastes, considering different incineration temperatures, and comparing different extractants. These publications provide a wealth of data on phosphorus and heavy metal release from ashes under different conditions and related to analysis of the ash mineralogy.

Fourteen extractants were tested (2020, 1): three mineral acids (sulphuric, hydrochloric, nitric), five organic acids, sodium hydroxide (alkali) and five chelating agents, comparing different extractant concentrations, ash/extractant ratios and contact times. For sewage sludge incineration ash, oxalic acid offered the best compromise between effective phosphorus leaching and limited heavy metal release, but sulphuric acid was most cost-effective.

Comparing extraction from three different biowaste ashes (sewage sludge, poultry manure, meat and bone meal) (2021, 2), showed that P-leaching effectiveness of the organic acids varied considerably with different mineralogy of the three ashes, whereas leaching by the inorganic acids was consistent.

In a third paper (2021, 3), the influence of incineration temperature on mineralogy and P-leaching and heavy metal leaching was studied for ashes from a laboratory muffle furnace (note: the muffle furnace was chosen for reasons of consistency but may not be representative of conditions in real sewage sludge incinerators where conditions vary depending on the technology). The sewage sludge was sampled from the storage bunker at Leuven wwtp, Belgium (Aquafin), where sludge is collected from wwtps operating enhanced biological P-removal as well as dosing iron or aluminium for chemical P-removal. The muffle furnace was operated at 550°C – 1100°C, for two hours. In this case, higher furnace temperatures across the tested range tended to result in lower heavy metal leaching, but temperatures above 900°C also resulted in reduced P-release, probably because mineralogy shifted at higher temperatures (increase in non-identified amorphous phosphate, decreases in crystalline calcium phosphate and amorphous iron phosphate), and because P was fixed into silicate melt at 1100°C. The reduction in P-leaching above 900°C was significant for mineral acids and very considerable for organic acids. The authors conclude that 800°C – 850°C is the optimal temperature range to generate an ash from which phosphorus can be readily leached with limited release of heavy metals, which is similar to the EU Industrial Emissions Directive requirement of a minimum ensured temperature of 850°C for 2 seconds.

2020, 1: “Closing the phosphorus cycle: Multi-criteria techno-economic optimization of phosphorus extraction from wastewater treatment sludge ash”, L. Luyckx et al., Science of the Total Environment 713 (2020) 135543 DOI.

2021, 2: “Linking Phosphorus Extraction from Different Types of Biomass Incineration Ash to Ash Mineralogy, Ash Composition and Chemical Characteristics of Various Types of Extraction Liquids”, L. Luyckx et al., Waste and Biomass Valorization volume 12, pages 5235–5248 (2021) DOI.

2021, 3: “Recovery of phosphorus from sewage sludge ash: Influence of incineration temperature on ash mineralogy and related phosphorus and heavy metal extraction”, L. Luyckx et al., J. Environmental Chemical Engineering 9 (2021) 106471 DOI.

Overview of sewage sludge regulations in Europe

Summary of limits for contaminants in sewage sludge (used on farmland) across EU Member States and challenges for regulating pollutants in the current EU Sewage Sludge Directive update. The paper notes that many Member States have set limits for one or more contaminants (for sludge used on land) stricter than those in the current EU Sewage Sludge Directive 86/278, resulting in a highly fragmented legal framework. Indeed, in some Member States (e.g. Austria) limits are different in each region. In some cases, limits are defined as a function of regional average soil values. The varying limits for As, Cd, Cr, Cu, Hg, Ni, Pb and Zn are represented in visual graphics. 19 (of 27) Member States have fixed lower limits for mercury, 18 for cadmium, 16 for nickel, 14 for copper and lead and 10 for zinc. Additionally, 23 Member States have fixed limits for chromium, 8 for arsenic, and one or two also for molybdenum, selenium and beryllium, whereas none of these are regulated by EC 86/278. Twelve Member States have fixed limits for certain pathogens in sewage sludge applied to land (different limits, different pathogens), whereas these are not regulated by 86/278. Some Member States have also fixed limits for organic pollutants regulated by 86/278 which are lower than the limits in this Directive (DEHP, LAS, NP/NPE, PAH, PCB, PCDD/F). The paper highlights the need to also address emerging contaminants, in particular PFOS/PFOA (perfluorinated chemicals) and microplastics. PFOS/PFOA are already regulated in sewage sludge in Austria and Germany. Microplastics are difficult to regulate because of a lack of knowledge on their behaviour and impacts in soil and plants, the absence of agreed protocols for quantifying and characterising microplastics in soils, and because they are widely present in soils irrespective of sludge spreading, because of other sources. The authors note the need to combine safe sewage sludge management, avoiding environmental or health risks, with nutrient recycling.

“Land Application of Biosolids in Europe: Possibilities, Constraints and Future Perspectives”, A. Gianico et al., Water 2021, 13, 103 DOI

Stay informed

SCOPE newsletter: www.phosphorusplatform.eu/SCOPEnewsletter

eNews newsletter: www.phosphorusplatform.eu/eNewshome

If you do not already receive SCOPE and eNews (same emailing list), subscribe at www.phosphorusplatform.eu/subscribe

LinkedIn: https://www.linkedin.com/company/european-sustainable-phosphorus-platform/

Slideshare presentations: www.slideshare.net/NutrientPlatform

Twitter: @phosphorusfacts

ESPP members