Newsletter about nutrient stewardship - European Sustainable Phosphorus Platform (ESPP)

Please subscribe www.phosphorusplatform.eu/Subscribe

Link to www.phosphorusplatform.eu/eNews073

Download as PDF

ESPP new members

C-Green

SNB

SOFIE and Nitrogen Recovery Workshop

Follow-up to successful events

What does the term “Bio-Based Fertiliser” mean?

EU Communication on “Bio-Based" and relevance to nutrients

Regulatory

Recovered struvite authorised in EU Certified Organic Farming

Lack of data on Cat1 ABP ash safety

Preparatory study for Sewage Sludge Directive (SSD) revision

Spanish Royal Decree on sustainable fertilisation in agriculture

CEN has published 82 Technical Specifications for fertilising products

Nutrient recycling

Updated inventory of operating P-recovery sites

Fluidised-bed sewage sludge recovery and ash reuse as fertiliser

Biogas digestate resources will be increase by five by 2050

Braunschweig sewage nutrient recovery trials

European Biochar Industry (EBI) position paper on pyrolysis of sewage sludge

Nutrient stewardship and food security

Global and European food security highly dependent on fertiliser supply

Scientists propose UK Phosphorus Transformation Strategy

NGOs welcome revised Urban Waste Water Treatment Directive (UWWTD) proposal

JRC study suggests EU+UK are accumulating 130 ktP/y in soil

Transgressing planetary boundaries for P and N

Stay informed

ESPP members

ESPP new members

C-Green

C-Green

C-Green has developed and patented OxyPower HTC™, converting sewage sludge, manure, and food digestate into solid hydrochar by a combination of hydrothermal carbonisation (HTC) and wet oxidation of the separated water. HTC or wet pyrolysis was invented in 1913 by the Nobel prize-winning German chemist Friedrich Bergius. Wet oxidation produces heat, which is used to heat the incoming sludge and to convert the nitrogen in the separated water into ammonium ions.

OxyPower HTC™ simplifies both nitrogen and phosphorus recovery. Nitrogen is extracted from the separated nitrogen-rich wet oxidized process water by ammonia stripping. Up to 60% of the nitrogen in the sludge is separated as ammonium sulphate.

OxyPower HTC™ simplifies both nitrogen and phosphorus recovery. Nitrogen is extracted from the separated nitrogen-rich wet oxidized process water by ammonia stripping. Up to 60% of the nitrogen in the sludge is separated as ammonium sulphate.

The hydrochar can be used as a biofuel or for soil improvement depending on local regulations. Mono-incineration of the hydrochar makes it possible recover phosphorus from the ash. NOx emissions are significantly lower compared to sludge incineration. In addition, more than 50% of the nitrogen in the sludge can be recovered as fertiliser.

If the hydrochar is used for soil improvement, virtually all phosphorus and up 90% of the nitrogen in the sludge (60% ammonia water and 30% in the hydrochar) is used.

C-Green is confident that membership in ESPP will help us contribute to developing sustainable carbon and nutrient recycling through information, monitoring, networking and contacts with decision makers.

Website: www.c-green.se

SNB

SNB

SNB, a Dutch company established in 1994 by Dutch Water Authorities, operates the largest sewage sludge incineration plant in Europe.  Their aim is to treat sewage sludge sustainably by recovery of energy and raw materials. Furthermore, they are engaged to reduce their environmental footprint, including the objective of carbon neutral sewage sludge treatment. Currently SNB processes about 410.000 to 430.000 tons of dewatered sewage sludge a year. Their strategic goal is to achieve circular sewage water and sludge treatment. To achieve this goal SNB is and has been involved with several partners to recovery phosphates from sewage sludge incineration fly ashes. These sludges contain phosphorus concentrations comparable to low grade phosphate rock. In addition to phosphate recovery, SNB is investigating recovery and recycling nitrogen from sewage sludge. As a member of ESPP, SNB contributes, together with the other members, to a phosphorus sustainable Europe by recovery of phosphates from waste, through research and by steering regulation towards a circular economy.

Their aim is to treat sewage sludge sustainably by recovery of energy and raw materials. Furthermore, they are engaged to reduce their environmental footprint, including the objective of carbon neutral sewage sludge treatment. Currently SNB processes about 410.000 to 430.000 tons of dewatered sewage sludge a year. Their strategic goal is to achieve circular sewage water and sludge treatment. To achieve this goal SNB is and has been involved with several partners to recovery phosphates from sewage sludge incineration fly ashes. These sludges contain phosphorus concentrations comparable to low grade phosphate rock. In addition to phosphate recovery, SNB is investigating recovery and recycling nitrogen from sewage sludge. As a member of ESPP, SNB contributes, together with the other members, to a phosphorus sustainable Europe by recovery of phosphates from waste, through research and by steering regulation towards a circular economy.

SOFIE and Nitrogen Recovery Workshop

Follow-up to successful events

ESPP’s January 2023 events, 2nd SOFIE and 1st Nitrogen Recovery Workshop, saw nearly 400 participants in Brussels and online. SCOPE Newsletter summaries of both events are currently being finalised.

Registered participants to each event already have full access to slides, session recordings, edited Chat, list of participants with emails (on Swapcard (for SOFIE) or via link sent for N-Recovery).

SOFIE2 (Summit of Organic and Organo-Mineral Fertilisers Industries in Europe) confirmed the considerable enthusiasm and interest in this growing and restructuring sector, which is strategic for the nutrient circular economy. SOFIE showed active engagement both by upstream sectors supplying raw materials (in particular digestates and compost, of which production is expected to grow considerably in the coming decade with EU biomethane and biowaste policies), organic fertiliser producers, processing equipment suppliers, and also the mineral fertiliser industry, motivated by complementarities between organic and mineral nutrients for crop nutrition and by market and logistics synergies. SOFIE is the only event for organic fertilisers industry, and the only place to meet this growing industry’s different partners.

SOFIE2 (Summit of Organic and Organo-Mineral Fertilisers Industries in Europe) confirmed the considerable enthusiasm and interest in this growing and restructuring sector, which is strategic for the nutrient circular economy. SOFIE showed active engagement both by upstream sectors supplying raw materials (in particular digestates and compost, of which production is expected to grow considerably in the coming decade with EU biomethane and biowaste policies), organic fertiliser producers, processing equipment suppliers, and also the mineral fertiliser industry, motivated by complementarities between organic and mineral nutrients for crop nutrition and by market and logistics synergies. SOFIE is the only event for organic fertilisers industry, and the only place to meet this growing industry’s different partners.

SOFIE3 is already fixed for 16-17 January 2024 (Brussels & hybrid)

Further information soon www.phosphorusplatform.eu/SOFIE

The Nitrogen Recovery Workshop showed strong interest in “White Nitrogen” (recovery and reuse of reactive nitrogen), accelerated by the current energy and fertiliser supply crisis. Technologies exist, some longstanding (stripping and scrubbing), some innovative and new, but with challenges of producing dilute solutions, logistics, cost. The workshop agreed the need to establish some form of working group to develop proposals on policy, R&D funding, information gathering and supply-chain networking and collaboration. A Steering Committee is now being established to take this forward and is open to companies and volunteers wishing to contribute.

The Nitrogen Recovery Workshop showed strong interest in “White Nitrogen” (recovery and reuse of reactive nitrogen), accelerated by the current energy and fertiliser supply crisis. Technologies exist, some longstanding (stripping and scrubbing), some innovative and new, but with challenges of producing dilute solutions, logistics, cost. The workshop agreed the need to establish some form of working group to develop proposals on policy, R&D funding, information gathering and supply-chain networking and collaboration. A Steering Committee is now being established to take this forward and is open to companies and volunteers wishing to contribute.

If you wish to be involved on Nitrogen Recovery, contact:

What does the term “Bio-Based Fertiliser” mean?

EU Communication on “Bio-Based" and relevance to nutrients

The European Commission has published a communication on the use of the term “Bio-Based Plastic” which can be seen as relevant for the term “Bio-Based Fertiliser”. The Communication refers to the CEN/TC4111 definition of Bio-Based (see below) and indicates that Bio-Based plastics are made from biomass, with a preference for organic wastes and by-products, whereas conventional plastics are made from fossil resources. The Communication notes that Bio-Based Plastics can be made fully or partly from biobased feedstock, but underlines that generic claims such as “biobased” may be banned by the Green Deal proposed directive “Empowering Consumers for the Green Transition”, unless underpinned by recognised environmental performance, and therefore that the exact and measurable share of biobased content should be specified (in a Bio-Based Plastic).

The CEN (TC4111) European Standard EN 16575 (August 2014) “Bio-based products: vocabulary” defines (2.1, 2.5) a bio-based product as “Wholly or partly derived from biomass. May have undergone physical, chemical or biological treatment” and (2.4) bio-based content as “fraction of a product that is derived from biomass. Normally expressed as a percentage of the total mass of the product”. Biomass is defined (2.7) as “material of biological origin excluding material embedded in geological formations and/or fossilised”. CEN has outlined methodology for quantifying the bio-based content of products in CEN/TR 16721. This takes as starting point the % of bio-based carbon based on C14 ratio. Unfortunately, this method does not seem appropriate for assessing whether N or P or K are “bio-based” when recovered from organic wastes.

ESPP notes that the term Bio-Based Fertiliser (“BBF”) is already being used in R&D publications (see e.g. Wester-Larsen et al. Lex4Bio 2022 in ESPP eNews n°72) and that a comparable discussion is ongoing concerning the wording “nutrients of solely biological origin” in the EU FPR (Fertilising Products Regulation).

ESPP considers that the definition and usage of these vocabulary terms are important for market clarity (product communication to users and consumers) and for a possible future European Standard on defining and measuring “Bio-Based nutrient” content (nutrients of “biological origin”) to support environmental claims and EU Fertilising Products Regulation certification.

ESPP is therefore developing a Position Paper on the definitions of “Bio-Based Fertiliser” or “Bio-Based Nutrient”.

This document is open to comment on the ESPP public website www.phosphorusplatform.eu. The objective is to achieve consensus on a proposed definition to submit for consideration by the European Commission and by CEN.

European Commission Communication COM(2022)682, 30th November 2022 “EU policy framework on biobased, biodegradable and compostable plastics” HERE

Regulatory

Recovered struvite authorised in EU Certified Organic Farming

The EU Organic Farming Regulations have been modified to authorise “Recovered struvite and precipitated phosphate salts”, as defined in the EU Fertilising Products Regulation (FPR). The modifying Regulation (2023/121 modifying 2021/1165), published 17th January 2023, specifies that, to be authorised for use in Certified Organic Farming, the recovered phosphates “must meet the requirements laid down in” the FPR and that “animal manure as source material cannot have factory farming origin”. ESPP notes that there is to date no official EU definition of “factory farming”. The European Environment Agency indicates a definition here and the EU Expert Group on Organic Farming (EGTOP 2013) refers to 1995 EU Guidance*. ESPP also notes that the modification to the Organic Farming Regulations does not include the words “and derivates” which are included in the FPR CMC12, suggesting that recovered precipitated phosphates can be used in Certified Organic Farming as such, but not after chemical reprocessing. ESPP further notes that the text specifies that the recovered precipitated phosphates must “meet the requirements” of the FPR, and does not state that they must be EU-Certified under the FPR. It could be surmised that this choice of wording means the precipitated phosphates must respect the criteria of FPR CMC12, and of at least one FPR PFC, and of FPR Labelling (Annex III), but do not require FPR Conformity Assessment (Annex IV), but this interpretation should be verified with national Certified Organic Farming implementation authorities. ESPP notes that the obligation to respect CMC12 excludes (for the present) any struvite or precipitated phosphates derived from manure or from other animal by-products (ABPs) (e.g. from digestate where manure [even if not from factory farming] or separately collected municipal biowaste are inputs to the digester), until the ABP Regulations are modified to include relevant ABP End-Points (amendment underway, see ESPP eNews n°71). It is ESPP’s understanding that under the wording of this amendment as proposed, precipitated phosphates derived from ABPs would only be authorised in the FPR CMC12 if (1) they are precipitated from digestate where the digestion process respects the Standard Processing Requirements of the ABP Regulation 142/2011 “standard” processing requirements (Annex V, ch. I, II and III) or (2) if the precipitated phosphate is sterilised according to the requirements of 142/2011 Annex XI, chapter I ($2 a, b & d, that is treatment at ≥70°C for ≥60 minutes), and (in both cases) if the processing plants were appropriately authorised and controlled by national ABP authorities.

Note: the German language published version of this Regulation contains a translation error (the materials are “deleted” from the list instead of being “added”). The European Commission is aware and correction is underway.

* 1995: Commission Guidelines for the use of excrements in organic farming (Annex II, part A, to Regulation (EEC) No 2092/91), VI/5684/95-EN Rev5(PPQPP/EN/95/5684R5.doc). These guidelines are out of date and refer to interpretation of “factory farming” in EU Regulation 2381/94 which has been repealed, but this used exactly the same wording “factory farming origin prohibited” as in the current Organic Farming Regulations which have replaced it. See reference to this 1995 document in a 2020 European Commission answer to the European Parliament (1/7/2020). This 1995 document is no longer available on the European Commission website and can be found on the ESPP website www.phosphorusplatform.eu/regulatory

Commission Implementing Regulation (EU) 2023/121 of 17 January 2023 amending and correcting Implementing Regulation (EU) 2021/1165 authorising certain products and substances for use in organic production and establishing their lists https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32023R0121

Lack of data on Cat1 ABP ash safety

Data search and analysis for ESPP concludes that incineration and co-combustion are not proved to inactive prions. Cat1 animal by-products represent a significant, high-quality potential for phosphorus recovery. ESPP considers that the priority is safety, and in particular inactivation of prions (which cause BSE, scrapie and other transmissible spongiform encephalopathies (TSE). A literature search, commissioned by ESPP to Dr Kevin McDonnell, University College Dublin, identified only 22 studies, recent or not, relevant to pathogen reduction in animal by-products by thermal/chemical processes, of which 13 reported pathogen reduction following thermal treatment. None of the studies addressed the specific conditions of the EU Industrial Emissions Directive IED (850°C, 0.2 seconds). Data suggests that increasing temperature and time improve prion deactivation. The only directly relevant studies (Brown et al. 2000 et 2004) use a highly heat resistant prion (strain 263K, comparable to BSE) and show >8 log 10 reduction at 612 °C for 15 min and total inactivation at 1 000 °C for 5 and 15 min. Dr McDonnell concludes that this does not enable conclusions concerning prion deactivation under EU IED conditions.

“Sanitary Safety of Animal by-product Ash”, K. McDonnell, UCD and Bio-e Biosystems, for ESPP, 47 pages, 2022, online here www.phosphorusplatform.eu/regulatory

“New studies on the heat resistance of hamster adapted scrapie agent: Threshold survival after ashing at 600°C suggests an inorganic

template of replication”, P. Brown et al. 2000, Proceedings of the National Academy of Sciences of the United States of America, 97(7), https://doi.org/10.1073/PNAS.050566797

‘Infectivity Studies of Both Ash and Air Emission from Simulated Incineration of Scrapie-Contaminated Tissues”, P. Brown et al. 2004, Environmental Science Technology, PP. 6155-6160. https://doi.org/10.1021/es040301z

Summary of the Brown et al. studies cited: Brown et al. 2000 tested injection of prion-infected brain material from hamsters into healthy hamsters, with or without dry heat combustion under air at 600°C or 1000°C. This showed prion reinfection after combustion at 600°C. Brown et al. (5 out of 35 healthy hamsters infected). Brown et al. repeated their trials because the results were surprising, taking precautions on possible contamination by combustion flue gases, and obtained the same results in the second study (2004). The authors note some residual organic carbon at 600°C. In the second study, samples were also heated under nitrogen, and in this case there was no reinfection at 600°C, leading the authors to conclude that incomplete combustion was not preventing prion deactivation. They hypothesise that at 600°C the prions are leaving an “inorganic template” (rather like a fossil) in the ash and that this template can cause refolding of healthy prions, so causing reinfection.

ESPP comment: The literature search conclusions and the Brown studies would seem to lead to the conclusion that there is today no evidence that IED incineration of Cat1 animal by-products ensures safety (prevents risk of TSE transmission). This is problematic, not only as regards possible use of Cat1 ash in P-recovery or fertiliser production, but also as regards current management of Cat1 by-products, which are currently incinerated under IED conditions.

ESPP plans to organise a webinar of concerned companies, stakeholders and experts, to discuss how to take forward these questions. If you are interested to input, please contact

Preparatory study for Sewage Sludge Directive (SSD) revision

EU preparatory study for the SSD concluding mainly that there is a lack of data of possible impacts of emerging pollutants, in particular pharmaceuticals, and also a lack of data on sewage sludge treatment and use. The report assesses implications for sewage sludge management of different current or anticipated EU policies. Risk assessment of different emerging pollutants in sludge are presented, including microplastics and antimicrobial resistance (AMR). For industrial chemicals, the highest PEC/PNEC ratios (indicator of potential risk) were for the brominated flame retardant Deca-BDE (BDE209) and for PAHs (poly aromatic hydrocarbons). PFAS were also identified as “of potential concern for human health” and some pharmaceuticals as possibly posing health risks through sludge use on soils. The contribution of sewage sludge to microplastic inputs to soils is considered small (most inputs to the environment are from vehicle tyre wear), and most sludge microplastics are fibres. Possible impacts of microplastics on soil, plants and health is considered to be poorly understood. The report underlines that data on how sewage sludge processing modifies emerging contaminant inputs to soil is inadequate and should be developed. The report also underlines that data on use routes for sewage sludge in Europe are incoherent and incomplete: unidentified “other” category is often reported, “Compost is reported as an end-use whereas it is in fact a pre-treatment before different destinations. Also, there is inadequate data as to how much sewage sludge undergoes anaerobic digestion, which impacts both final sludge volumes and energy recovery. The report notes that phosphorus can be recovered by different routes. Application of sludge to agricultural land “remains a key end-of-life option”, ensuring nutrient return to agriculture, with currently around one third of EU sewage sludge used in this way. However, the report notes that “future trends for use of sewage sludge on land are not clear … there are uncertainties with regard to the environmental impacts, specifically linked to pollutants of emerging concern”.

“Support to the evaluation of the Sewage Sludge Directive. Exploratory study - final report”, Wood, Trinomics, Ricardo, IMDEA, Tyrsky, March 2022 https://dx.doi.org/10.2779/582221

Spanish Royal Decree on sustainable fertilisation in agriculture

National Decree requires farmers to record all nutrient and organic carbon applications and implement a fertilisation plan, and specifies conditions for recycling secondary materials as fertiliser coherent with the EU FPR. The 43 page Decree states as context the EU Green Deal targets to reduce nutrient losses by 50% by 2030 without deteriorating soil fertility. It sets as aims to ensure farmers planning of and recording of fertilisation, define good agriculture practices for nutrient application (including of fertilisers, manures, sewage sludge and other secondary materials), establish by 2026 a mandatory register of manufacturers and other economic agents for fertilisers, define conditions under which waste and secondary materials can be either used in fertilising products (this largely refers to the EU Fertilising Products Regulation criteria) or applied as waste, define accreditation and intervention of “technical fertilisation advisors” to farmers. Farmers and foresters will be obliged to record all applications of nutrients or of organic carbon to soil in a new “fertilisation” section of the existing log established for phytosanitary products. Farmers will have to define a fertilisation plan, using soil and leaf analysis data, and this must prioritise the use of organic fertilisers and must include measures to mitigate ammonia and greenhouse gas emissions. Reference to a fertilisation advisor will be obligatory for these plans in Nitrate Vulnerable Zones. The Decree also includes measures concerning heavy metal limits in fertilisers and in soils, storage and application of manures, limiting ammonia emissions from urea fertilisers (reference is made to the UNECE document “Options for ammonia mitigation”).

Spain Royal Decree 1051/2022 (27th December 2022) establishing legal standards for sustainable nutrition in agricultural soils - Real Decreto 1051/2022, de 27 de diciembre, par el que se establecen normas para la nutrición sostenible en las suelos agrarios https://www.boe.es/eli/es/rd/2022/12/27/1051

CEN has published 82 Technical Specifications for fertilising products

In April 2022, CEN published 82 new Technical Specifications to support implementation of the EU Fertilising Products Regulation. This is expected to be followed, after laboratory validation, by European Standards. The new Technical Specifications cover testing methods, sampling methods, terminology and concern soil improvers and growing media (CEN/TC 223), fertilisers and liming material (CEN/TC 260) and plant biostimulants (CEN/TC 455) and cover aspects such as terminology and classification, determination of physical properties and particle size, determination of nitrogen of different forms in organic and mineral fertilisers, determination of water soluble -, citric acid soluble -, formic acid soluble – and NAC soluble – phosphorus in fertilisers, determination of potassium, magnesium, calcium and micro-nutrients contents, nutrient release from coated fertilisers, determination of total organic carbon content …

“CEN published 82 new Technical Specifications on fertilizing products in support of the EU Circular Economy objectives”, 21st April 2022 HERE.

Nutrient recycling

Updated inventory of operating P-recovery sites

The worldwide inventory list of operating full-scale installations for P-recovery from wastewater treatment (Christian Kabbe, P-REX Environment) is updated online here. The inventory list has been fully updated, and identifies around 75 installations operating worldwide as currently operational and recovering phosphorus, of a total of around 120 installations listed. The technology supplier, the location, operating since, the recovered phosphate material/product and the annual tonnage of product output are specified. Christian Kabbe notes that these outputs are nominal capacities, whereas plants often produce significantly less. With units expected to come online this year, there will be around 45 struvite plants operational in Europe, producing struvite containing c. 2000 tP/y. This compares to expected recovery of around 50 000 tP/y from sewage sludge incineration ash in Germany alone, when the German P-recovery obligation comes fully into application (in 2032).

“Inventory of phosphorus “recovery and /or recycling” facilities operating or under construction at or downstream of wastewater treatment installations” v 11/2022 here: https://www.phosphorusplatform.eu/activities/p-recovery-technology-inventory

Fluidised-bed sewage sludge recovery and ash reuse as fertiliser

Published paper presents ENDEV PAKU new-design sewage sludge incinerator achieves energy neutrality and ash of around 5% P content, successfully tested in continuous-operation 10 000 t/y dried sludge input pilot. The process developed by ESPP member ENDEV takes mechanically dewatered sewage sludge (20 - 25% DM), dries it at 110°C then mixes with sand and combusts at 850°C / 2 seconds (respecting IED requirements) in a double circulating fluidised bed dryer / incinerator designed to optimise energy. Organic contaminants and microplastics in sewage sludge are eliminated, and heavy metals are partly volatilised. Around 8% of mercury, 5% of zinc and 4% of copper are thus effectively removed from the ash to the flue gas filter waste stream. Sulphur is removed from flue gases by scrubbing. The pilot installation was constructed at Rovaniemi municipal sewage works, Finland (63 000 p.e., probably using iron for chemical P-removal), treating all the works sludge, and has now today been operated for nearly two years, producing around 1 MWh heat per tonne of mechanically dried sewage sludge. The scale and compact design enable at medium size sewage works, avoiding sewage sludge transport. Heavy metal contents of the ash are significantly lower than EU Fertilising Products Regulation limits for As, Cd, Cu, Hg, Ni, Pb, Zn but phosphorus solubility at 65-70% in NAC is too low for labelling as phosphate fertiliser under the EU Fertilising Products Regulation..

Published paper presents ENDEV PAKU new-design sewage sludge incinerator achieves energy neutrality and ash of around 5% P content, successfully tested in continuous-operation 10 000 t/y dried sludge input pilot. The process developed by ESPP member ENDEV takes mechanically dewatered sewage sludge (20 - 25% DM), dries it at 110°C then mixes with sand and combusts at 850°C / 2 seconds (respecting IED requirements) in a double circulating fluidised bed dryer / incinerator designed to optimise energy. Organic contaminants and microplastics in sewage sludge are eliminated, and heavy metals are partly volatilised. Around 8% of mercury, 5% of zinc and 4% of copper are thus effectively removed from the ash to the flue gas filter waste stream. Sulphur is removed from flue gases by scrubbing. The pilot installation was constructed at Rovaniemi municipal sewage works, Finland (63 000 p.e., probably using iron for chemical P-removal), treating all the works sludge, and has now today been operated for nearly two years, producing around 1 MWh heat per tonne of mechanically dried sewage sludge. The scale and compact design enable at medium size sewage works, avoiding sewage sludge transport. Heavy metal contents of the ash are significantly lower than EU Fertilising Products Regulation limits for As, Cd, Cu, Hg, Ni, Pb, Zn but phosphorus solubility at 65-70% in NAC is too low for labelling as phosphate fertiliser under the EU Fertilising Products Regulation..

“A novel dual circulating fluidized bed technology for thermal treatment of municipal sewage sludge with recovery of nutrients and energy”, P. Petlola et al., Waste Management 155 (2023) 329–337, DOI. See also ESPP-NNP-DPP Nutrient Recycling Technology Catalogue.

Biogas digestate resources will be increase by five by 2050

The EBA Statistical Report 2022 provides detailed assessment of biogas production in Europe today and trends, concluding that digestate resources (220-260 Mt fresh weight/y today) will double by 2030 and increase five-fold by 2050. The European Biogas Association (EBA) combines data from national biogas associations, national statistics and industries in EU plus 6 adjacent countries, and presents detailed analysis and graphs. The report concludes that by 2050 biogas and biomethane* (from anaerobic digestion) could provide 35 – 60% of Europe’s gas consumption. This is driven by EU policies towards renewable energies, and accelerated by the current gas supply and price crisis. This will result in a several-fold increase in digestate production, providing a key resource of secondary nutrients. Estimates of nutrient content suggest that digestate today contains 0.5 - 0.6 Mt N-NH4/y, expected to increase to 2.6 -3.1 Mt by 2050, and 0.4 – 0.5 MtP/y, increasing to 2.0 – 2.3 MtP. This corresponds, for 2050 estimates , to around 26% - 31% of today’s synthetic N fertiliser consumption and c. 86% for synthetic P fertiliser (2050). Digestate also brings, today, around 5 Mt/y of stable organic carbon to agricultural soils.

“Statistical Report 2022. Tracking biogas and biomethane deployment across Europe”, European Biogas Association, December 2022, 160 pages, price on request here https://www.europeanbiogas.eu/SR-2022/EBA/

* “Biogas” is the combustible gas generated by anaerobic digestion of organic materials, consisting mostly of methane, but with some other gases. “Biomethane” is high-purity or refined biogas, consisting almost solely of methane, and which can be reinjected into natural gas distribution networks to replace fossil methane. For definitions see: https://www.europeanbiogas.eu/about-biogas-and-biomethane/

Braunschweig sewage nutrient recovery trials

Three-year, full-scale tests at 380 000 p.e. wwtp assess thermal pressure sludge hydrolysis (TPH), anaerobic digestion, struvite precipitation and ammonium sulphate recovery. Identifying benefits, operating challenges and parameters. In the C19th sewage nutrients were recycled by spreading sewage on farmland, after primary treatment since the 1950’s. From 1979, the waste water treatment plant (wwtp) integrated secondary treatment and anaerobic sludge digestion, with the digested sludge continuing to be used on farmland (storage in winter to enable use in summer only). However, nitrogen application limits since 2016 has led to 40% of sludge being incinerated. In 2019, for circularity objectives, thermal hydrolysis was added between two sludge digestion stages, with struvite precipitation in the digestate dewatering liquor, and ammonia recovery by stripping from the digestate liquor. Optimal conditions for the thermal pressure hydrolysis were identified through the trials as around 145°C, 4 bars, 1 ½ hours. The resulting breakdown of the sludge led to a +20% increase in biogas production, resulting in more than enough additional secondary heat after electricity generation to heat the TPH. After two years of process optimalisation reliable struvite recovery (without loss of fines, >80% P precipitation in reactor) was achieved with the NuReSys reactor. With the TPH in place, around 15% of total P in sludge was recovered in struvite, operating with MgCl2 dosing at around 2:1 Mg:P ratio and pH 8.5 (NaOH dosing). This is not sufficient to achieve the German P-Recovery Ordinance obligations, because the dewatered sludge exceeds 20 g P/kg DM. Some 250 t/y of struvite are now being produced, and this is fairly pure, with < 0.5% calcium, potassium, iron etc and heavy metals below German fertiliser legislation levels (organic contaminants not reported). The ammonia stripping unit was operating on digestate with c. 1200 mgNH4-N/l and optimal conditions were identified as pH 9.5 (NaOH dosing) and temperature 55°C (heating needed). This generated an ammonium sulphate solution of concentration about 38 % based on weight. This is conform to German fertiliser legislation requirements and is distributed locally by a third party in the region so ensuring effective recycling to crop production.

“Technology related results of the case study Braunschweig (DE)”, A. Kleyöcker, J. Heinze, F; Kraus, 10/2022, EU Horizon 2020 funded, online here.

European Biochar Industry (EBI) position paper on pyrolysis of sewage sludge

Policy paper concludes that pyrolysis removes most organic pollutants from sewage sludge. The paper requests a review of the current exclusion of sewage sludge from pyrolysis and gasification materials in the EU FPR (Fertilising Products Regulation CMC14). The 14-page paper explains the pyrolysis process and the resulting material, biochar. Evidence is summarised (based on 10 studies plus 2 review papers) indicating that pyrolysis eliminates pathogens and organic pollutants (including PFAS, PAH, microplastics), on condition that the pyrolysis temperature and residence time are sufficient [ESPP note: probably a minimum temperature of maybe 500°C – 650°C is required, see ESPP SCOPE Newsletter n°144, whereas the EU FPR CMC14 allows temperatures down to 180°C so adjustment would be necessary]. Evidence is also summarised indicating that biochar contributes to carbon storage in agricultural soils and can be a negative carbon emissions fertiliser. Phosphorus in sewage sludge biochar seems to be slowly crop available, with NAC solubility generally up to 80% [ESPP note: in this case, cannot be labelled as a phosphorus fertiliser under the EU FPR, Annex IV, part II, PFC1 point 4(b)]. Pyrolysis is considered as scalable for medium or large sewage works (> 20 000 p.e.). It is noted that sewage sludge biochar can be used in agriculture under national regulations such as in the Czech Republic, Denmark and Sweden.

EBI (European Biochar Industry) is an ESPP member since January 2023.

“Sewage Sludge as feedstock for pyrolysis to be included in the scope of the EU Fertilizing Products Regulation”, EBI Position Paper sent to the European Commission, 23 January 2023 https://www.biochar-industry.com/2023/ebi-position-paper/

Nutrient stewardship and food security

Global and European food security highly dependent on fertiliser supply

Modelling of agricultural input shocks impact on crop production shows that fertiliser supply is highly critical to global food security, with risks of 30 – 50% crop production losses, especially in Western Europe and the USA. This paper models impacts on crop yield of hypothetical reductions in supply of different agricultural inputs (fertilisers, machinery, pesticides) for 12 crops for which relevant data was found (barley, cassava, groundnut, maize, millet, potato, rice, sorghum, soybean, sugar beet, sugarcane and wheat), 25 climate types and different countries or continents. A “random forest” modelling method was used, because this has been shown to applicable to crop yields. Generally, input shocks impacted crops in climate types with highest current yields. Reductions in fertiliser inputs (in particular N, and in some cases K) cause the most significant crop yield losses. A 50% reduction in N-fertiliser inputs would case a25% - 75% reduction in wheat yield in much of Western Europe and in parts of North and South America, Asia and Southern Africa. A 50% reduction in all of the modelled agricultural inputs would reduce maize production by 30% in China, around 50% in France and in the USA, 70% in Argentina and would reduce wheat production by 40 – 50% in Germany and France, around 20% in Australia and Canada and 10% in the USA. Worldwide wheat production could be reduced by 30% and maize production by 50% with a 75% reduction in all modelled agricultural inputs. The authors underline the dependency of crop yields, and so food security, on global trade flows of fertilisers and other agricultural supplies.

“Agricultural input shocks decrease crop yields globally”, A. Ahvo et al., Research Square preprint December 2022 DOI.

Scientists propose UK Phosphorus Transformation Strategy

Researchers conclude the 4-year RePhoKUs project with the co-development of six key strategic pathways for the UK food system to transition to a desirable phosphorus future. Based on consultation with around 60 stakeholders, the scientists assessed the UK’s phosphorus vulnerability, finding that the UK imports nearly all the phosphorus in processed fertilisers used in the UK, and around half of the phosphorus in processed animal feeds (not including locally used manure, grass and fodder). They estimate that theoretically the UK has nearly enough phosphorus circulating in the food system to be self-sufficient, based in part on the analysis that only 43% of P imported (total of 172 ktP/y net, in fertilisers, chemicals, animal feed, food products) ends up in food products. Their P-flow analysis for the UK suggests that 48 ktP/y is lost to water and landfill, which is around 30% of net imported phosphorus; They estimate that nearly 90 ktP/y is accumulating in agricultural soils due to over application, principally driven by manure application. [Note: this is coherent with UK official Defra data but is contradictory to Panagos et al. below]. The report underlines significant regional phosphorus imbalances have resulted from high concentration of livestock production in North West England, Wales and Northern Ireland, while the South East cropping regions remain in phosphorus deficit [this is also the conclusion of Panagos et al. see below]. The researchers suggest that over-application of phosphorus in manure to farmland in England’s North West alone is equivalent to almost 30 million UK£/year of phosphorus fertiliser (not including nitrogen).

The report concludes that the current linear phosphorus use coupled with fragmented governance has led to serious water pollution, trade security risks and regional imbalances that are costly and inefficient. It analyses vulnerability to different agricultural sectors to fertiliser price increases and identifies structural obstacles to more sustainable P management. Cost is identified as a major obstacle, both cost of P-recycling (e.g. manure processing) and cost of recycled P products.

The report concludes that actions are needed to render coherent the institutional framework, raise awareness, bring together different stakeholders and develop targets and indicators for P sustainability for different sectors or scales (e.g. catchments, supermarket chains) and proposes the establishment of a “government supported” national phosphorus platform.

Below: stakeholder vision for a transformed phosphorus management system for the UK (RePhoKUs 2022).

RePhoKUs partners: Lancaster University, University of Leeds, University of Technology Sydney, AFBI, UK CEH. Funded by UKRI under the UK’s Global Food Security research program.

“UK Phosphorus Transformation Strategy. Towards a circular UK food system”, RePhoKUs, D. Cordell et al., 2022, HERE.

“A new direction for tackling phosphorus inefficiency in the UK food system”, RePhoKUs, S.Rothwell et al., 2022, HERE.

“Regional phosphorus imbalances” - interactive maps. RePhoKUs. 2021, HERE

“Phosphorus in the UK Food System: risks and opportunities” RePhoKUs animation HERE

NGOs welcome revised Urban Waste Water Treatment Directive (UWWTD) proposal

Environment associations joint position welcomes UWWTD revision proposal, especially treatment of further pollution sources, circular economy and polluter pays principle. The NGOs call to apply the “zero pollution hierarchy” to sludge. The joint EEB (European Environment Bureau), Surfrider, Health Care Without Harm (HCWH) position welcomes the proposed requirement of energy-neutrality for the wastewater treatment sector by 2040 [art.11] (inc. anaerobic digestion of sludge) and proposed monitoring of greenhouse gases [art.21.1d]. The NGOs welcome the proposed empowerment of the European Commission to set minimum recycling rates for phosphorus and nitrogen [art.20]. The position states that “while it is essential to favour recovery of resources from wastewater and sludge, the risk of contamination and the associated limits for direct reuse needs to be acknowledged”. The NGOs request that treatment of sludge should be based not only on the “Waste Hierarchy” [this is already specified in art.20] but also on the “Zero Pollution Hierarchy” defined in the Green Deal Zero Pollution Action Plan, that is “Prevent” above “Treat”, application of the Precautionary Principle and of Polluter Pays. ESPP is not clear as to what this would mean in implementation for sewage sludge. The NGO’s welcome the proposed Extended Producer Responsibility (EPR) to require producers and importers of pharmaceuticals and cosmetics to cover costs of monitoring and removing these (in wastewater treatment) [art.9].

“Joint NGO Analysis of the European Commission’s Proposal for a Revised UWWTD”, EEB – Surfrider – HCWH, 14th December 2022, 7 pages HERE.

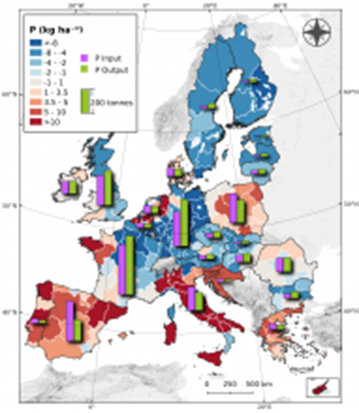

JRC study suggests EU+UK are accumulating 130 ktP/y in soil

Data on soils, crops, fertilising inputs, erosion losses, etc. suggests average P surplus of 0.8 kgP/ha/y for EU+UK, with very wide regional variations. This suggests considerable opportunities for improvement in phosphorus management by reducing inputs in regions with high surplus and high available soil P and increasing inputs in regions at risk of soil fertility depletion. This study follows on from the study estimating phosphorus offtakes in crops and crop residues in EU+UK published earlier in 2022 (see ESPP Scope Newsletter n°142). With the new study, JRC makes available online P budgets (inputs – outputs) at the NUTS2 (regional) and at country scale, and also a dataset for both Total P and Olsen P (available P) based on LUCAS (Land Use/Cover Area frame Survey) topsoil data. The study estimates that EU+UK topsoil (173 million ha, 0 – 20 cm depth) contains an average of 1 400 kgPtotal/ha (total 245 Mt P), but that < 6% of this is available to crops (POlsen). The study estimates that inorganic fertilisers and manure contribute similar levels of P in fertilisation (both c. 7.6 kgP/ha/y = total 1.3 MtP/y). This assumes that 90% of manure phosphorus is applied locally as organic fertilisation. Displaced P lost from fields by erosion and sediment flux is estimated at c. 2 kgP/ha/y (370 ktP/y EU+UK) but only around 18% (66 ktP/y EU+UK) of this is considered to be lost to surface waters (the remainder being redeposited in soil close to the field of loss). The study includes visual maps illustrating, for regions across Europe, soil P stocks, mineral fertiliser use, manure, P erosion, P losses to surface waters, phosphorus budget (excess or deficit). The majority of European regions show a P-surplus (121 regions of 223). Most of Northern and Central Europe (except The Netherlands, Belgium and Western France) shows a P deficit, as does Scandinavia. The largest P surpluses (as tP/country) are Spain, Italy and Poland (fig. 9) and the largest P surpluses (per hectare) are Malta, The Netherlands, Italy, Belgium, Denmark and Ireland (fig. 10). Regional variations are considerable, Brittany France has a P-surplus of > 10 kgP/ha/y whereas parts of Northern/Central France show a deficit <-8 kgP/ha/y.

Data on soils, crops, fertilising inputs, erosion losses, etc. suggests average P surplus of 0.8 kgP/ha/y for EU+UK, with very wide regional variations. This suggests considerable opportunities for improvement in phosphorus management by reducing inputs in regions with high surplus and high available soil P and increasing inputs in regions at risk of soil fertility depletion. This study follows on from the study estimating phosphorus offtakes in crops and crop residues in EU+UK published earlier in 2022 (see ESPP Scope Newsletter n°142). With the new study, JRC makes available online P budgets (inputs – outputs) at the NUTS2 (regional) and at country scale, and also a dataset for both Total P and Olsen P (available P) based on LUCAS (Land Use/Cover Area frame Survey) topsoil data. The study estimates that EU+UK topsoil (173 million ha, 0 – 20 cm depth) contains an average of 1 400 kgPtotal/ha (total 245 Mt P), but that < 6% of this is available to crops (POlsen). The study estimates that inorganic fertilisers and manure contribute similar levels of P in fertilisation (both c. 7.6 kgP/ha/y = total 1.3 MtP/y). This assumes that 90% of manure phosphorus is applied locally as organic fertilisation. Displaced P lost from fields by erosion and sediment flux is estimated at c. 2 kgP/ha/y (370 ktP/y EU+UK) but only around 18% (66 ktP/y EU+UK) of this is considered to be lost to surface waters (the remainder being redeposited in soil close to the field of loss). The study includes visual maps illustrating, for regions across Europe, soil P stocks, mineral fertiliser use, manure, P erosion, P losses to surface waters, phosphorus budget (excess or deficit). The majority of European regions show a P-surplus (121 regions of 223). Most of Northern and Central Europe (except The Netherlands, Belgium and Western France) shows a P deficit, as does Scandinavia. The largest P surpluses (as tP/country) are Spain, Italy and Poland (fig. 9) and the largest P surpluses (per hectare) are Malta, The Netherlands, Italy, Belgium, Denmark and Ireland (fig. 10). Regional variations are considerable, Brittany France has a P-surplus of > 10 kgP/ha/y whereas parts of Northern/Central France show a deficit <-8 kgP/ha/y.

European Commission JRC summary (ESDAC European Soil Data Centre) “Phosphorus budget and P stocks” LINK.

“Improving the phosphorus budget of European agricultural soils”, P. Panagos et al., Science of the Total Environment 853 (2022) 158706 DOI.

Transgressing planetary boundaries for P and N

Scientists suggest that Western Europe is exceeding the “share” of planetary boundary for P annually by 3-4x and for N by 4-5x. For Eastern Europe, significant exceedance is not identified. The exceedance is higher for P and similar for N considering accumulated share since the 1950’s. The “share” is based on agricultural land surface (crop plus grass), not on population. Worldwide, exceedance was driven mainly by economic growth, not population growth. Exceedance estimates are based on the most recent nutrient planetary boundary estimates (Carpenter and Bennett 2011, Steffen et al. 2015,de Vries et al. 2013, following Rockström et al. 2009 & 2009), that is 6.2 MtP/y and 62 MtN/y. Around half of the accumulated exceedance for phosphorus and nitrogen are in China, the USA plus India (because of their large agricultural areas), whereas countries with highest exceedance of share (taking into account agricultural area) include South Korea and the Netherlands for N and Japan and South Korea for P. The authors suggest that future allocations of fair shares of nutrient planetary boundaries should consider transfer of nutrients from global regions with accumulated share exceedance over past decades to those low cumulative nutrient use, in particular Africa.

“Disparate history of transgressing planetary boundaries for nutrients”, V. Sandtröm et al., Global Environmental Change 78 (2023) 102628, DOI.

Stay informed

SCOPE Newsletter: www.phosphorusplatform.eu/SCOPEnewsletter

eNews newsletter: www.phosphorusplatform.eu/eNewshome

If you do not already receive ESPP’s SCOPE Newsletter and eNews (same emailing list), subscribe at www.phosphorusplatform.eu/subscribe

LinkedIn: https://www.linkedin.com/company/phosphorusplatform

Slideshare presentations: https://www.slideshare.net/phosphorusplatform

Twitter: @phosphorusESPP

YouTube https://www.youtube.com/user/phosphorusplatform

ESPP members