The George Barley Water Prize (Everglades Foundation) has named its first winner as WETSUS Netherlands, with the NaFRAd project (Natural Flocculation Reversible Adsorption). WETSUS (European Centre of Excellence for Sustainable Water Technology) takes home the US$ 25 000 prize for the Prize Stage 1. After winning Stage 1, the Wetsus team is now preparing its submission for the second stage which requires testing and demonstrating at the laboratory lab scale.

Stage 2 of the Prize is open to organisations worldwide, whether or not they participated in Stage 1. Deadline: 15th July 2017, see below.

The WETSUS NaFRAd technology proposes a combination of flocculation with natural flocculants and reversible adsorption with high capacity iron based adsorbents. This can remove both particulate and soluble phosphorus with minimal waste generation. The phosphorus can be recovered as calcium phosphate for use in the fertiliser industry. These technologies reflect the WETSUS research themes Phosphate Recovery and Natural Flocculants.

WETSUS is a partner of the European Sustainable Phosphorus Platform, and has for example developed with ESPP a regularly updated listing of publications providing overviews and comparisons of phosphorus recovery technologies (http://www.phosphorusplatform.eu > Activities > P-recovery Technology Inventory). WETSUS also regularly provides articles for ESPP’s SCOPE Newsletter reviewing scientific publications on phosphorus recycling technologies.

Photo: March 22, West Palm Beach, Florida: George Barley Water Prize Stage 1 winner WETSUS, represented by Prasanth Kumar , with Nathalie Olijslager-Jaarsma, Consul General of the Netherlands, Jim King, Scotts Miracle Gro, Mary Barley, Board Member of the Everglades Foundation and Eric Eikenberg, CEO of the Everglades Foundation.

Stage 2 now open for submissions

Stage 2 of the Prize is currently open for applications from teams capable of testing their solution for two consecutive weeks processing c. 24 litres/hour (see exact specifications in application materials). Applicants will submit daily inflow and outflow samples from their technology. A total of $80,000 will be awarded in November of this year to the top 3 teams in Stage 2. Applicants to Stage 2 need not have applied to Stage 1. The deadline to request Stage 2 application materials is 15 July 2017 and the deadline to submit applications is 31 August 2017.

The Pilot Stage, the third stage of the George Barley Water Prize, will qualify 10 teams to compete at a Pilot location in Canada in early 2018, with awards totalling $800,000. Finally, the Grand Prize will see the top 4 teams compete in Florida for the ultimate $10 million award.

15 Stage 1 finalists

Stage 1 of the George Barley Water Prize is the first milestone of the 4-year prize which will reward with US$ 10 million the most cost-effective, scalable technology that thoroughly removes and recovers phosphorus from freshwater bodies. Over 75 applicants from all over the globe submitted proposals to Stage 1 (from a total of 181 initial entries). Entries came primarily from the United States, but also from Canada, India, Belgium, Germany, Australia, China, Japan, Indonesia, Netherlands, Ireland, Sweden and Israel. The prize nominated 15 finalists for Stage 1, and these are summarised below.

George Barley Water Prize, funded by the Everglades Foundation and with support from Ontario, Xylem, Miracle Gro and Knight Foundation http://www.barleyprize.com

The 15 stage 1 finalists are as summarised below

(see also on the Prize website: go to “Entries” and search by project name)

The fifteen George Barley Water Prize Stage 1 finalists:

Technologies including phosphorus adsorbents

- Wetsus NaFRAd (Natural Flocculation Reversible Adsorption) – winner of Stage 1 of the Prize - particulate phosphorus is captured by biodegradable bioflocculants, soluble phosphorus is captured in an adsorbent bed which can be regenerated using calcium hydroxide for recovery of calcium phosphate. Adsorption is part of the WETSUS Phosphate Recovery theme with participation of Delft University of Technology, STOWA, ICL Fertilizers, KEMIRA, Green Water Solution, water authority Brabantse Delta and Oosterhof Holman. Natural flocculants are being developed in the WETSUS Natural Flocculants theme with participation of Wageningen University Research, Pentair and Shell Global Solutions. See on YouTube and https://www.wetsus.nl/phosphate-recovery Contact See photo.

- Rocky Mountain Scientific APR – proposes a compound (APR1 beads – a proprietary compound) which enables phosphorus to be removed from water by adsorption/desorption. Contact

- AquaCal AgBag – uses “biogenic oolitic aragonite”, which means a form of calcium carbonate in spherical grains produced by biological processes (this is not clarified). It is claimed that “adding aragonite into animal and plant nutrition … will mitigate the very generation of phosphorus by livestock and farming activities”. Clarifications have been requested by ESPP, because we do not understand how adding calcium carbonate can have the result that phosphorus going into one end of animals does not come out the other end (phosphorus present in animal feed comes out in manures except for the non significant and essentially non variable amount stocked in bones etc). The answer we received from the company was that this is currently undergoing testing. It is also proposed to install different types of filter bags of aragonite in field drainage or storm water collection to adsorb phosphate. It is indicated that the phosphorus-enriched calcium carbonate can then be used as a fertiliser or soil improver.

- WAVVE Stream / University of Houston spin-off – using nano-coated polymer beads to adsorb nutrients and heavy metals, with regeneration capabilities. Website: http://wavvestream.com Contact

Biological systems

- AquaFiber Technologies AquaLutionsTM process – lake water is pumped through a patented unit at the heart of which is a dissolved air flotation unit modified to maximize its efficiency to harvest the smallest algal cells from the lake water. The system also includes gravity pre-separation and biological polishing. Clear, clean and oxygenated water is returned to the source and blue-green algae are removed. The harvested biomass can be used to produce an organic fertiliser or converted to energy. A 14 million litres/day, 0.4 ha footprint (of which 7% for the treatment installation) site has already been tested successfully at Lake Jesup, Florida, 2009-2014. The technology is ready for roll-out and the company offers a “pay for performance” business model. www.aquafiber.com See photo.

- Phosphorus-hungry microbes (PIARCS) – microbes are used to remove soluble phosphorus from water and stably sequester it as polyphosphate. Advantages over conventional bio-P removal are very rapid phosphate uptake, without subsequent phosphate release. The rapid uptake means that fermenter-grown microbes can be added just prior to flocculation. The polyphosphate rich biomass can be used as organic fertiliser. Contact

- Wetlaculture (Mitsch) – landscape-scale and mesocosm-scale models integrating wetlands for phosphorus retention with agriculture. Retained phosphorus in the wetlands is directly recycled as fertiliser to crops appropriate for temperate or subtropical region. See photo.

High technology solutions

- Nutrient Extraction and Recovery Devices (University of Maryland Baltimore County) – selective phosphorus uptake and recovery using ion exchange membranes and high-strength monovalent salt solutions. Contact

- Waterway Nanoshield (University of Calgary) – phosphorus removal from livestock manure using nanoporous carbon membranes as electro-filters, to clean water and produce “mineral concentrates” of phosphorus and nitrogen which can be redistributed as a fertiliser. Contact

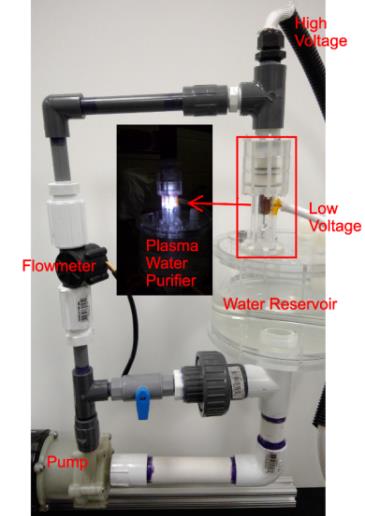

- Plasma Water Reactor – University of Michigan – plasma injection into water is indicated as having the following effects: changing water chemistry (oxidation states, pH) so initiating precipitation of ions such as phosphates; electrical enhancement of coagulation; generation of ozone, UV … which break down organics. See photo.

Iron-based phosphorus removal

- Waterloo Biofilter EC-P System – low-energy electrochemistry releases ferrous iron into septic systems or ditch water to remove phosphorus as inert, crystalline iron phosphate minerals (vivianite). This is similar to the use of iron salts for P-removal in sewage works worldwide, but without P-rich sludge production. The process can be modified to recover iron phosphate crystals which are proposed for use as a fertilising soil amendment. www.waterloo-biofilter.com Contact See photo.

- P removal (University of Miami) – using riparian buffer vegetation zones, waste iron materials from foundries for phosphorus adsorption and plants (reedbed type systems) for final purification stage removing low levels of phosphorus and other pollutants. Contact

- FIU ROAR (Florida International University) - submission from Everglades region presenting a “holistic approach”. Little technical information. Iron coated fibres used for P-removal – not defined how to dispose of or recycle these fibres after phosphorus uptake.

- Team blueXgreen - University of Idaho – reactive filtration using iron salts, biochar (from agriculture or forestry greenwaste) and ozone. Two first generations of the technology (ferrous iron and ozone) are operating commercially (Nexom/Blue Water Technologies) with installations up to >50 million litres/day, and are participating in the UK-WIR-CIP2 trials (see ESPP eNEWS n°7). The third generation reactive filtration technology (at pilot stage, see photo) adds biochar as a catalyst and phosphorus adsorbant. This can be recycled as a slow release phosphorus fertiliser which sequesters CO2. Photo: University of Idaho N-E-W Tech™ process research trailer. See https://www.youtube.com/watch?v=xI22R6vzVdw Contact See photo.

- US Geological Survey (USGS Leetown) –adsorption using mine waste ochre (iron oxide based) with regeneration of the ochre using sodium hydroxide, and then precipitation of calcium phosphate for recycling. See details in “Removal of phosphorus from agricultural wastewaters using adsorption media prepared from acid mine drainage sludge,” Sibrell, et al., 2009, http://dx.doi.org/10.1016/j.watres.2009.02.010 and “Fixed bed sorption of phosphorus from wastewater using iron oxide-based media derived from acid mine drainage” Sibrell and Tucker 2013 http://dx.doi.org/10.1007/s11270-012-1262-x

Contact See photo.

This report of the The George Barley Prize is here available in PDF.